It’s by no means excellent when a last pressure motor stalls or will get jammed, particularly at the task website online. However right here’s an overview of conventional reasons and the way we diagnose them.

Listed below are a couple of Store Communicate Weblog posts it’s possible you’ll in finding fascinating:

3 major issues can result in a jammed or stalled ultimate pressure motor: put on, lubrication problems, or issues of the rotator staff at the hydraulic aspect. Here is how you’ll be able to determine which one is the issue.

Put on

Each and every mechanical gadget and element will enjoy commonplace put on that can in the end result in failure — and that’s true of ultimate drives, too. Bearings, gears, shafts, and seals all have a restricted lifestyles. So changing portions as they put on out is significant to keep away from cascade harm to different portions.

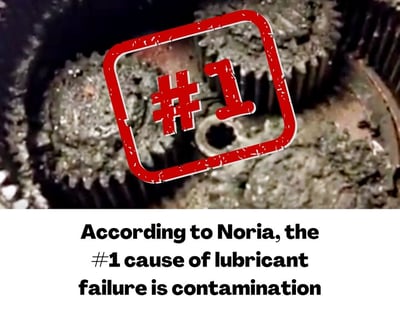

Customary mechanical put on will also be sped up through overloading the gadget, no longer offering sufficient lubrication, and permitting an element to fail with out changing it. Remember the fact that, this ends up in a last pressure planetary hub that wears out a lot quicker than it will have to. Put on will also be sped up through overheating and particulate contamination, as proven under.

One of the crucial insidious sides of mechanical put on is that it will probably temporarily turn out to be a cycle that can overall your planetary pressure. As an example, it could get started with steel flakes coming off some of the bearings. That steel flake will glide round within the lubrication. All the way through use, it will probably temporarily be compelled between two contacting equipment enamel or between bearing surfaces. There it will probably motive any other particle to wreck off. And the extra steel debris and slivers there are, the speedier steel contamination is generated. So in the end, the planetary equipment set will likely be totaled.

Lubrication Problems

With out sufficient lubrication, your planetary will enjoy sped up put on made worse through generated contamination. A leaking seal could cause it, so checking your equipment oil ceaselessly is necessary. And if you end up time and again having to most sensible off your equipment oil degree. If so, the issue is a leaking seal that must be sorted instantly. Too little equipment oil ends up in put on, identical to we mentioned previous.

Every other factor with equipment oil that can result in a stalled ultimate pressure motor is outdated, infected equipment oil. As equipment oil ages, probably the most components we rely on for its efficiency will start to damage down chemically — which is why you will have to exchange it consistent with producer suggestions or it’s possible you’ll finally end up with a large number like this.

Consider: a leaking seal no longer most effective signifies that equipment oil can leak out, however abrasive contamination from the paintings website online could make its method in and result in severe harm.

Diagnosing a Stalled Ultimate Force

So, how do our techs handle a last pressure that involves our store stalled or jammed? Right here’s our method:

- Take a look at equipment oil for indicators of contamination

- Take a look at planetary gears for harm

- Take a look at rotating meeting

Take a look at Equipment Oil

Get started with the equipment oil at the planetary aspect. First, get a container large enough to catch the equipment oil and mean you can visually take a look at it for steel debris because it drains out. Steel debris — flakes, slivers, chunks, debris — are the herbal results of put on. Additionally, some drain plugs are magnetic, so we advise having a look at them to look if any steel flakes or debris are caught to them. Proven under is an instance of outdated equipment oil this is most likely doing extra hurt than excellent.

When you see steel flakes, slivers, or chunks at the plugs or within the equipment oil, that’s an indication of damage to the purpose that the surfaces of gears, splines, and bearings are breaking off. And as they damage off, they generate much more harm in an unforgiving cycle. By the point you’ve were given sufficient slivers, chunks, and debris to look on your equipment oil, you’ve were given critical harm that can most likely require rebuilding the planetary.

If the equipment oil popping out is blank and transparent, you wish to have to test for problems throughout the planetary hub. And that results in your next step.

Take a look at Planetary Gears

First, take away the quilt plate (and we all know that may be more uncomplicated stated than carried out). As soon as the quilt plate is off, investigate cross-check the gears for cracks and splines that would motive the pressure to jam. Additionally, take a look at the bearings. When you see no harm within the equipment aspect, however the pressure nonetheless is not going to transfer, the issue will likely be at the hydraulic aspect. The in all probability factor is an issue with the rotating meeting.

Take a look at Rotating Meeting

Subsequent, we open up the hydraulic aspect to test the rotating meeting (additionally known as the rotator staff). There, we search for anything else that forestalls it from transmitting movement. As an example, the picture under presentations critical sufficient harm to jam the general pressure motor.

Here is an instance of bearing failure within the rotator staff — the technician’s finger is pointing at shattered bearing parts.

And in a radial piston motor, this will surely deliver a last pressure motor to a prevent.

Conclusion

This can be a tough define of troubleshooting a stalled or jammed pressure motor or observe pressure. We’re going to gladly let you over the telephone or by the use of electronic mail you probably have any questions.