When hurrying to reassemble your ultimate pressure motor, it’s tempting to torque one bolt and transfer directly to the following adjoining bolt. However that isn’t a smart selection. On this Store Communicate Weblog put up, we’ll talk about why the collection during which you tighten bolts is vital after which take a look at what can cross incorrect whilst you don’t.

.png?width=600&height=600&name=Bolt%20Torquing%20Sequence%20for%20Final%20Drive%20Motors%20(4).png)

Listed below are a couple of different Store Communicate Weblog posts you may experience:

Bolts fall beneath the class of mechanical fasteners whose process is to carry issues in combination. Bolts no longer simplest dangle your ultimate pressure in combination, however in addition they dangle your pressure motor in your device. We all know they should be extraordinarily robust, taking into account the huge power inside your ultimate pressure. Then again, how you put in and torque them can compromise their talent to carry issues in combination.

Significance of Tightening Bolts in a Series

Listed below are the 3 key the reason why bolt tightening collection is vital:

- Succeed in uniform load distribution

- Keep away from phase distortion

- Attaining a excellent seal

When bolts are in the proper collection, uniform load distribution is accomplished. Every bolt carries roughly the similar load, which may also be crucial when top pressures and forces are concerned, like those that attempt to pressure ultimate pressure hubs aside. That is particularly vital when a gasket is concerned.

Right here’s every other side of uniform load distribution: flanges want to come in combination slowly and be parallel. To succeed in this, the proper collection is wanted, and a number of other tightening passes are wanted, expanding the burden every time.

When the burden is uniformly dispensed, phase distortion is minimized, like warping or deformation. We’ve almost certainly all skilled this when running with plastic or sheet steel.

In case you are fastening the hubs of your ultimate pressure in combination, you need to connection to be robust and dependable — and that ceaselessly comes to a excellent seal. If the bolts aren’t sporting a uniform load, gaps between the surfaces might permit contaminants in and fluids out.

What Can Occur When an Unsuitable Series is Used

So what occurs when an wrong bolt tightening collection is used? Smartly, we talked concerning the significance of a uniform load distribution. An asymmetric load distribution could cause some spaces to be beneath a lot upper tension than others, resulting in untimely failure.

For thick flanges, distortion might appear not going till you believe the intense temperatures and forces concerned all over day-to-day use. And distortion may end up in improper capability or even untimely failure. And warping can have an effect on the seal accomplished between the 2 mating surfaces, resulting in leaks of power or fluid that simplest happen when your apparatus has been working for some time.

Some other attainable drawback that stems from wrong sequencing comes to the potential for misalignment, which will have an effect on efficiency and capability. And, as mentioned with distortion and sealing, it should simplest display up as soon as the portions concerned have heated up all over use.

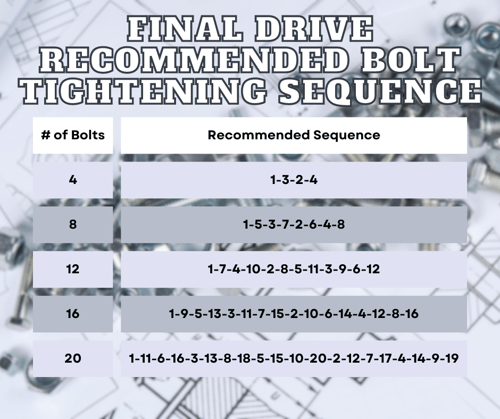

Bolt Torque Series

An respectable ASME PCC-1-2019 usual is thought of as the “go-to” documentation for bolting requirements associated with flange joints. Its complete identify is “Power Boundary Bolted Flange Joint Meeting,: but it surely’s 114 pages lengthy — so let’s simply summarize best possible practices right here on this infographic:

Conclusion

Taking the time to tighten bolts within the beneficial collection contributes to the well being and function of your ultimate pressure motor. And do not fail to remember that right here at Texas Ultimate Force we additionally use Loctite Threadlocker on bolts to additional ensure that their integrity and scale back attainable corrosion problems.