Mechanical fasteners sign up for issues in combination, whether or not bolts keeping the hubs of your ultimate force motor in combination or a circlip used to stay the duvet plate in position. On this Store Communicate Weblog put up, we’ll discover the various kinds of fasteners you might to find for your ultimate force motor.

Desk of Contents

Bolts

My first creation to nuts and bolts got here younger with the Superb Bolt and Play Development Set. I found out that nuts and bolts cling issues in combination. In the actual international, when specified and put in accurately, bolts can cling parts at the side of huge forces or pressures seeking to separate them.

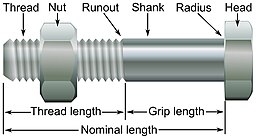

Fundamental Bolt Dimensions

For overview, listed here are the elemental dimensions of a bolt:

- Thread

- Runout

- Shank

- Radius

- Head

Supply: Mikael Häggström, CC0, by means of Wikimedia Commons

Word that the nominal duration of the bolt extends from the pinnacle’s within floor to the bolt’s finish. The nominal duration contains the thread duration and the grip duration (the a part of the bolt that doesn’t have threads). Bolts even have a small radius the place the shank meets the pinnacle to forestall a pressure focus.

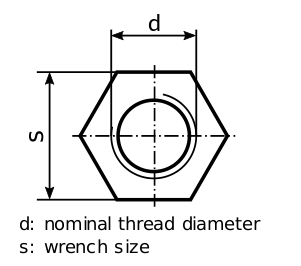

Supply: By way of Undfuld35 – Personal paintings, CC0, Wikimedia Commons

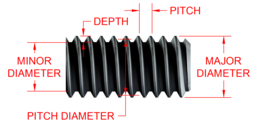

Every other vital facet of bolt dimensions is the bolt head itself, as illustrated above. Extra the most important than the bolt head, alternatively, are the thread dimensions. Within the symbol underneath, you’ll be able to see the

- Pitch

- Main diameter

- Minor diameter

- Pitch diameter

- Intensity

Supply: Robert Hewitt, CC BY-SA 3.0 by means of Wikimedia Commons

How Bolts Paintings

When the nut is tightened, it strikes alongside the bolt threads (which act like tiny susceptible planes) to near the distance between the fixed portions. Because the bolt is torqued, it develops a rigidity power alongside the duration of the bolt. This reasons the bolt to behave as a spring (which may be why they are able to come aside reasonably violently after they damage).

This spring power acts as a clamp keeping the 2 parts in combination. When the nut is loosened, that clamping power is launched. This clamping power additionally flippantly distributes the burden around the parts it’s fastening in combination, fighting subject matter deformation.

Do not overlook that a very powerful facet of ways bolts paintings invovles torquing and the order wherein they’re torqued — and some great benefits of the usage of a threadlocker.

Bolt Power Grades

Metal bolts are to be had in numerous power grades.

SAE Bolt Grades: That is the principle requirements for bolt power grades in the USA and are set in keeping with a gadget evolved through the SAE (Society of Car Engineers). The SAE marking gadget makes use of raised dashes at the bolt head. Those raised dashes are used to signify power. Here’s a desk explaining SAE bolt grade symbols.

Metric Bolt Grades: Metric bolt grades are set in keeping with ISO (Global Requirements Group) regulations. The grades consist of 2 numbers separated through a dot, and the valuables elegance is expressed in raised or depressed numbers discovered at the most sensible or at the aspect of the bolt head. Here’s a desk explaining metric bolt grades.

ASTM Bolt Grades: The ASTM (American Society for Checking out and Fabrics) established the foundations for those bolts. A mixture of letters, numbers, and features signifies the power grades. You’ll to find extra details about those on this desk explaining ASTM bolt grades.

Making sure that you are the usage of the fitting power grade bolts together with your ultimate force can assist scale back the probabilities of failure.

How Bolts are Categorised

There are a number of alternative ways to categorise bolts, and also you’re most definitely acquainted with all of them.

Usual vs Metric: Bolts are categorized through the usual they observe: metric, measured in millimeters, or imperial, measured in inches. The criteria additionally have an effect on the thread pitch or the space between threads. That’s why forcing an ordinary nut on a metric normally ends up in stripped threads.

Head Kind: Bolts could have other head sorts, equivalent to hexagonal, sq. (which rings a bell in my memory of Erector Units), Phillips, slotted, socket, and so on. The pinnacle sort normally determines how the bolt will probably be tightened/loosened: wrench, socket, or screwdriver, as an example.

Bolt Dimension: Bolts also are categorized through dimension, together with their diameter, duration, and thread pitch.

Thread Protection: Some bolts are absolutely threaded with little to no grip duration, whilst others are partly threaded. The selection between those depends upon the precise utility and the fabrics being fixed.

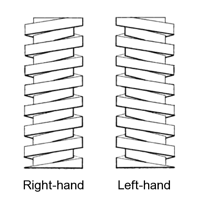

Thread Course: As you recognize, maximum bolts are right-hand threaded, which means they tighten clockwise. On the other hand, left-hand threaded bolts exist and tighten counter-clockwise. You’ll normally see them in particular programs to forestall loosening because of the course of motion.

Supply: Eugene Wycliffe Kerr, Public area, by means of Wikimedia Commons

Bolt Fabrics

Bolts are comprised of carbon metal, stainless-steel, alloy metal, titanium, aluminum, or even plastic. The number of subject matter depends upon the appliance, required power, and environmental stipulations. And the fabric used impacts the power grades. Bolts will also be lined to strengthen their sturdiness and resistance to corrosion. Zinc plating, galvanizing, and black oxide are not unusual bolt coatings, and the number of which to make use of closely depends upon their operating surroundings.

Washers

Whilst now not strictly fasteners, washers are steadily used with bolts to (1) higher distribute the clamping power and/or (2) make certain the nut or bolt head is pressed in opposition to a easy floor to assist save you sluggish loosening through the years.

What Can Washers Do

What can washers do inside a last force motor?

- Distribute the burden of a threaded fastener

- Lock the fastener to cut back the probabilities of it operating free through the years

- Offer protection to surfaces from attainable injury brought about through a washing machine

- Take in vibrations

- Save you leaks in a joint

Varieties of Washers

As you’ll be able to see underneath, there are lots of various kinds of washers. Let’s focal point at the washers you are going to in all probability come upon in a last force motor.

By way of ArnoldReinhold on the English-language Wikipedia, CC BY-SA 3.0, Wikimedia Commons

Flat washers serve a number of functions, equivalent to distributing the clamping power, protective the outside of fixed pieces, and correcting the scale of a gap. Because the title implies, they’re flat (not like Belleville or wave washers), and their dimensions are described in the case of thickness, interior diameter, and outer diameter. They’re to be had in many various sizes, fabrics, and finishes. Simple washers are very similar to flat washers however are thicker. They are able to additionally distribute the burden higher as a result of they supply a better floor space.

Lock washers are used to additional save you nuts and bolts from coming free, both via rotation or a lack of friction and feature some spring-like tab to assist lock them in position. Cut up washers are cut up with each and every finish bent outward and in reverse instructions. Those are also referred to as helical washers. When absolutely tightened, one finish digs into the nut/bolt whilst the opposite digs into the mating floor.

The exterior teeth lock washing machine is extra star-shaped, with enamel at the out of doors diameter to “chew” into the fastener. They’re steadily used when a wide-headed fastener is concerned. There also are inside teeth lock washers that still dig into the fastener when absolutely tightened. They’ve two not unusual makes use of: scenarios the place there may be numerous surprise and vibration and programs the place a shallow-headed fastener must be locked into position.

There are various kinds of spring washers, which allow them to transport with vibrations and observe a versatile pre-load to a bolted joint.

Belleville washers are flat washers which were pressed right into a cone form, which is why they’re also known as conical spring washers. They’ve beveled aspects that may make stronger heavy forces with little or no deflection. Those washers will also be stacked in numerous configurations to supply other spring traits. You’ll normally see Belleville washers utilized in higher-friction programs the place surprise and vibration results could cause fasteners to loosen. They’re additionally utilized in programs the place important temperature adjustments can have an effect on the clamping power. How a lot they are able to deflect depends upon the ratio in their peak and to their thickness.

Crescent washers, like Belleville washers, are designed for lighter so much and feature the similar spring fee all over their deflection vary. They paintings perfect for programs the place so much range cyclically and are steadily used to soak up motion.

Dome spring washers seem like Belleville washers however have rounded aspects and will maintain a lot increased so much. You steadily see them in scenarios that might use a crescent washing machine however desire a extra flat bearing floor.

Every other form of spring washing machine it’s possible you’ll come upon are wave washers. They’re curved in two instructions to reach a wave-like form and will behave as a spring when compressed. The spring impact is helping to care for the clamping power of the fastener. On the other hand, they’re usually utilized in low-strength programs.

When Mechanical Pins Are Used

Listed below are some conventional examples of when mechanical pins must be used:

- An enduring joint isn’t required and the gadgets to be joined want with the intention to be disassembled simply

- The gadgets to be joined are matter to vibration or surprise, which is not unusual in programs equivalent to hydraulic pumps and ultimate drives

- The gadgets to be joined are made of various fabrics

- The gadgets wish to be exactly aligned for the most productive efficiency

Pins

Pins, equivalent to dowel or cotter pins, are used to lock two or extra portions in combination and are normally carried out along side holes within the fixed portions, as you’ll be able to see underneath the place a cotter pin is used to safe the clevis pin in position. Along with fastening, they are able to additionally help in alignment and save you portions from transferring.

Supply: I, Sakurambo, CC BY-SA 3.0, by means of Wikimedia Commons

Varieties of Pins

Listed below are probably the most various kinds of pins:

Coiled pins: Coiled pins are very similar to slotted pins, however the sheet steel is coiled right into a spiral. This makes them extra immune to pulling out.

Cotter pins: A cotter pin, or a cut up pin or cotter key, is used to safe a nut or bolt. They’re inserted throughout the hollow within the nut or bolt, and the tines are bent in reverse instructions to forestall the pin from popping out. Cotter pins are usually used when the nut or bolt is matter to vibration or surprise.

Dowel pins: Dowel pins are cast cylindrical pins used to align two gadgets or save you them from rotating.

Grooved pins: Grooved pins have 3 or extra grooves alongside their duration. Those grooves intrude with the outlet’s partitions, making putting off the pin harder.

Slotted pins: Slotted pins are comprised of sheet steel rolled right into a cylinder. They’ve a slot operating alongside their duration, which permits them to be inserted and got rid of simply.

Spring pins: Spring pins are comprised of spring metal. They’ve a coil spring within that expands when the pin is inserted. This makes them self-locking, so they don’t wish to be secured with a nut or washing machine.

Circlips

Supply: Oxensepp at German Wikipedia, CC BY-SA 2.0 DE, by means of Wikimedia Commons

Circlips are nice till they bend otherwise you would not have the fitting gear to get them out. That may create some issues — however in a different way, they do a very good process.

What’s a Circlip?

A circlip, often referred to as a keeping ring, snap ring, or C-clip, is a mechanical fastener used to retain parts on a shaft or in a bore.

It is mainly a semi-flexible steel ring with open ends that may be positioned right into a machined groove at the shaft or bore. As soon as in position, the circlip prevents the part from transferring axially (in or out).

Varieties of Circlips

The most straightforward varieties of circlips are inside and exterior. Interior circlips are compatible within a housing or shaft. They’ve two open ends and are bent to shape a U-shape. You’ll be able to usually see this used to retain an element in a bore.

Exterior circlips are designed to suit round a bore. Like the inner circlip, they’ve two open ends which are bent, however they shape extra of a C-shape than a U-shape. Those circlips you’ll be able to see keeping an element on a shaft.

A Circlip in a Ultimate Power Motor

The commonest form of circlip is a undeniable cord ring, as noticed within the video underneath, however there also are circlips with lugs or ears that lead them to more straightforward to put in and take away.

On this video, a easy cord circlip is doing an out of this world process of keeping this Kayaba quilt plate from a Kubota KX121 in position — it is so laborious to take away that perhaps it is doing too excellent of a role.

Conclusion

The fasteners for your ultimate force motor are crucial to its proper operation and function. In case you have any questions on them (e.g., correct one ot use, how to take away, and so on.) ship us an e-mail or give us a choice.