Working out Steam Rollers with Bumps

The picture of a steamroller pulling down a street is almost certainly the primary symbol that involves thoughts when most of the people take into consideration development apparatus. In reality, there may be every other form of this heavy-duty apparatus that some other people would possibly in finding puzzling: the steamroller with bumps.

Lately within the development trade, this type of device is referred to as a padfoot curler or a sheepsfoot curler, relying at the form of the protrusions. Even supposing the phrase steam curler is a connection with the coal-powered engines used within the nineteenth and early twentieth centuries, the trendy compactor is diesel-powered and has long past moderately some way.

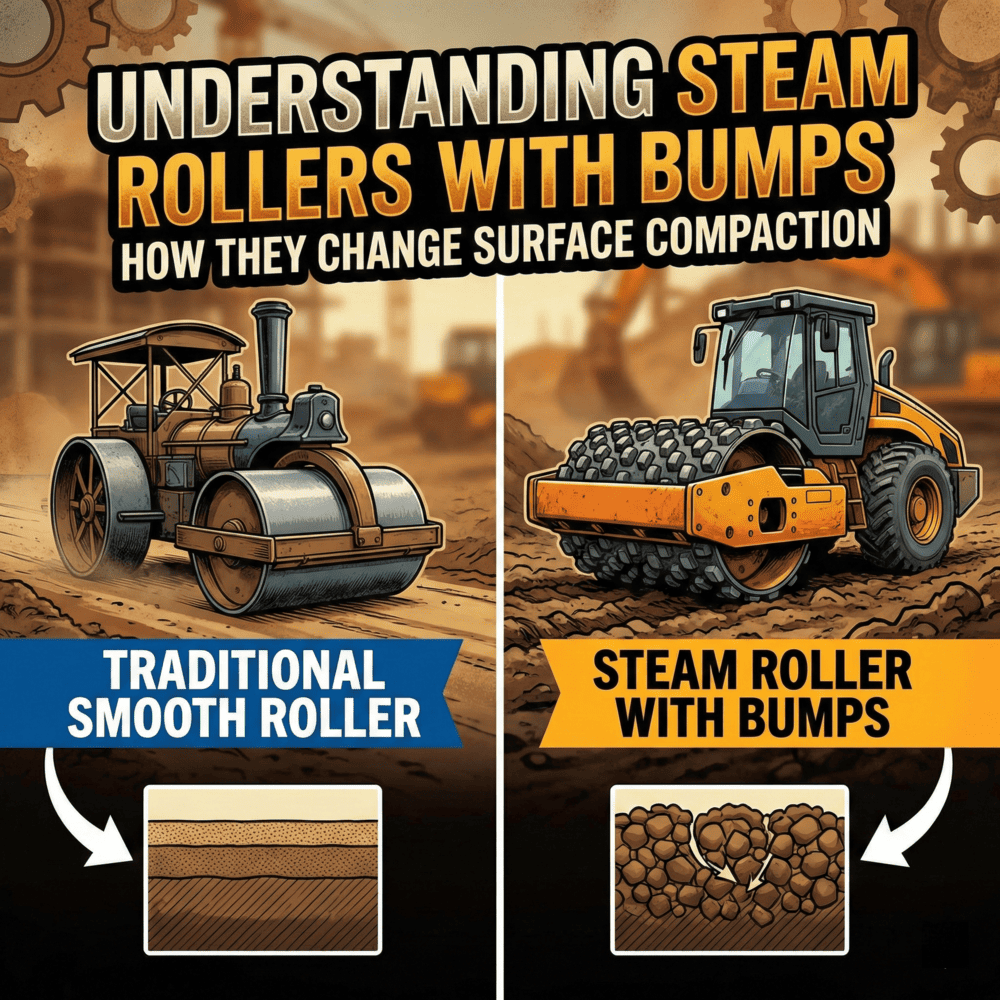

The bumps or ft at the drum aren’t there simply to be other however are an overly vital engineering approach to the hardest flooring prerequisites. The delicate drum rollers can not do extra than simply seal the outside of unfastened fabrics similar to sand and gravel. On the other hand, a padfoot curler is made to paintings the soil deeper.

The device to start with makes use of its distinctive kneading motion to eliminate air voids and moisture from cohesive soils, i.e., clay and silt thereby, giving a solid base that won’t transfer or crack from the so much in a while. Working out how those machines serve as can very much help mission managers and apparatus operators achieve the easiest flooring steadiness.

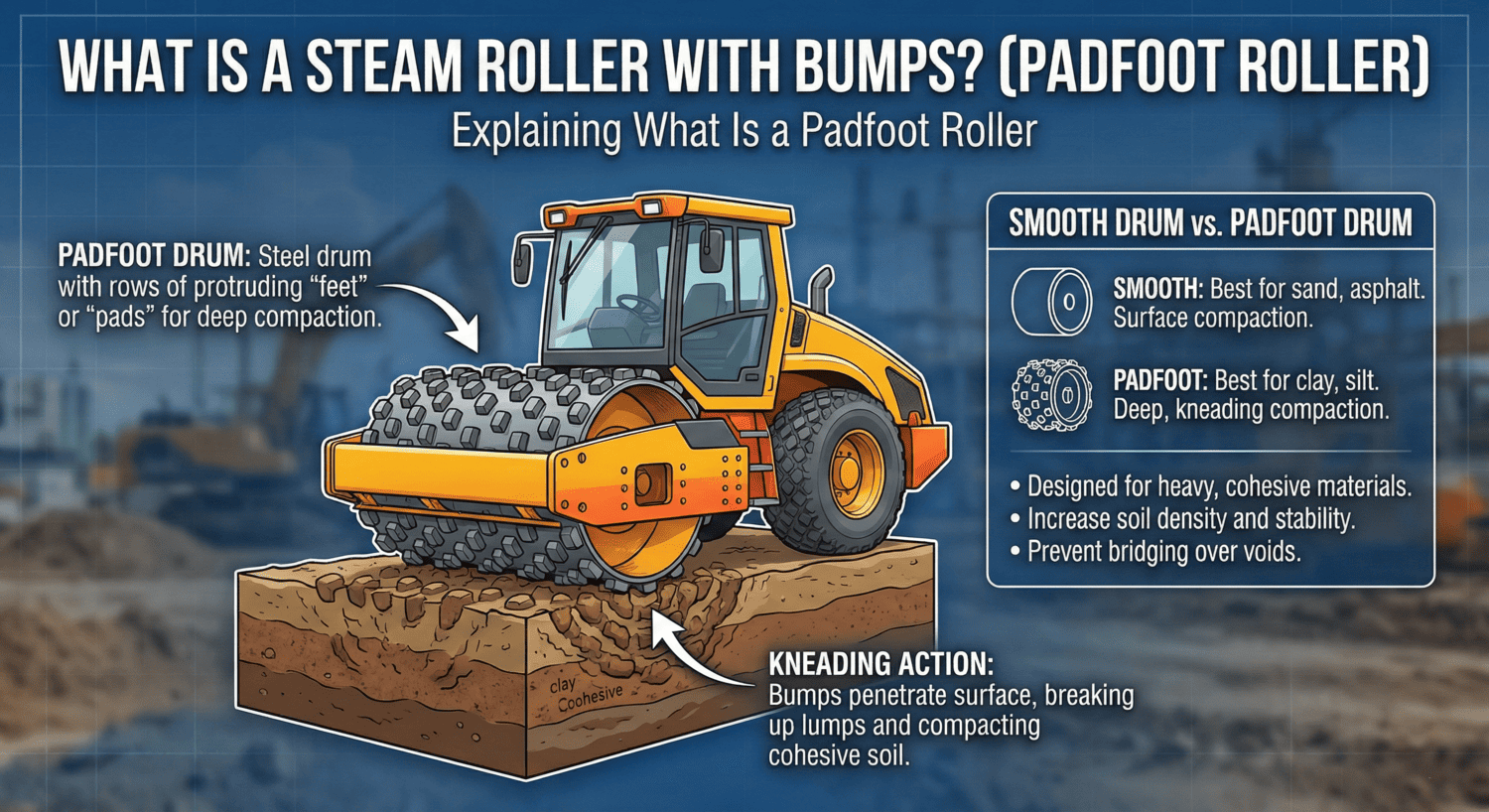

What Is a Steam Curler with Bumps? Explaining What Is a Padfoot Curler

A steam curler with bumps is in fact a soil compactor with a studded drum that was once discovered within the photos. The studs, technically known as lugs, pads, or tamping ft, protrude from the outside of the metal drum, they usually serve to penetrate the bottom.

At the moment, the primary fashions had been almost certainly horse-drawn or steam-powered, they usually had been known as sheepsfoot rollers since the development of impressions in the world seemed like sheep within the dust.

The padfoot curler lately marks a jump ahead within the building of this concept, applying geometric, tapered pads that supply higher self-cleaning and make allowance for upper compaction forces. Such equipment could be very useful in heavy civil engineering, because it is in a position to create a kind of compaction {that a} standard delicate drum is completely incapable of.

Those machines don’t best exert drive at the grime but in addition trick the grime debris right into a tightly packed, interlocking association.

- Distinctive Drum Design: The drum of the padfoot curler is roofed in protrusions (pads) product of metal which may be round, oblong, or tapered shapes, to call a couple of, against this to delicate rollers.

- Historic Context: The “sheepsfoot” time period originated from the previous manner of the usage of sheep to trample the unfastened grime, which become the muse for the mechanical “curler with bumps.”

- Number one Serve as: The primary function of those compactors is to create very top drive on the level of each and every pad in order that the drive can penetrate deeply into the soil.

Science At the back of the Pads—Running of Pads

The name of the game to a padfoot curler’s good fortune is its capacity of imparting manipulative pressure or kneading to the soil. If you’re taking as an example a delicate curler on clay, it is going to simply create a bridge over the hollows with the rolling and seal the outside, thereby trapping the air and moisture.

That is the perfect state of affairs for the formation of what’s referred to as a false compaction, the highest floor of which seems to be arduous whilst the subsurface is vulnerable and risky. The pads on a padfoot curler stay the curler from sealing the outside of the soil.

Similar to a baker kneads the dough, the pads penetrate the soil vertically after which as they depart at an perspective they thrust or knead the soil. This motion separates the tiny clay debris that experience sturdy herbal bonds and flattens the microscopic air voids that experience occupied the debris thereby making the soil dense and powerful.

- Breaking Bonds: There may be an higher drive through the very tip of the pad that is helping the disintegration of soil debris to be rearranged to acquire a better density from the ensuing compaction.

- Backside-Up Compaction: Those pads destroy in the course of the layer to succeed in and compact the decrease layers first, and then they regularly ‘stroll out’ of the soil because the layer turns into denser.

- Moisture Regulate: Via regularly expanding the outside space in touch with air and pushing out the water, the kneading motion facilitates the efficient drying of a humid soil.

Supreme Soil Varieties: Why Cohesive Soil Wishes a Padfoot Curler

Selecting the proper piece of apparatus relies only on the type of soil you will paintings on, and a padfoot curler is without a doubt how one can move whether it is cohesive soil you might be coping with. Cohesive soils, i.e., clay and silt, have the valuables of sticking to one another and preserving a large number of water.

They’re plastic (which means that that molding and deforming may also be performed with out cracking). When compaction is completed on heavy clay with a delicate drum device, the device will both slip or slide, or there will probably be this “pumping” phenomenon that occurs the place the soil strikes like a waterbed according to your steps.

The tapered pads of a padfoot compactor are made to punch via this resistance. The use of a padfoot device on granular soil like blank sand or gravel has the other impact; the ft will simply act like a tiller and unfasten the sand as an alternative of packing it down.

- Clay and Silt Dominance: Those rollers can in reality make a large distinction when used on herbal subject matter with a top plasticity index.

- Top Moisture Tolerance: The facility of delicate drums to take care of soil with little or no water is well known, however padfoot drums can move even additional in that admire through combating the drum from sliding because of the pads that act like brakes.

- Combating Bridging: It’s the small issues of each and every pad that be sure drive is exerted at the soil construction relatively than being on most sensible of arduous clumps.

Padfoot vs. Clean Drum: Evaluating the Two

In an effort to know the actual worth of a padfoot curler, the most efficient factor to do is to have a look at it facet through facet with a delicate drum curler. At the moment, each machines have the similar elementary chassis and propulsion programs, however the way in which they move about being in touch with the bottom is other.

The sleek drum will depend on each its weight and vibration to reason a settling of debris, somewhat like a shaker field. The padfoot rolls around the flooring through impacting and manipulating the debris. In lots of street development tasks, those two machines are used in combination: one padfoot curler to create the specified structural energy and the opposite delicate drum curler to “seal” the outside through night out the dimples from the pads in order that water can run off it as an alternative of ponding.

| Characteristic | Padfoot Curler (Sheepsfoot) | Clean Drum Curler |

| Number one Mechanism | Kneading and Affect (Manipulative Drive) | Static Power and Vibration |

| Highest Soil Kind | Cohesive (Clay, Silt, Heavy Soil) | Granular (Sand, Gravel, Asphalt) |

| Floor End | Dimpled, tough texture (will increase friction) | Clean, sealed floor |

| Compaction Route | Backside-up (Walks out of the elevate) | Best-down (Floor drive) |

- Power Switch: The power from the padfoot curler is transferred deeper into the elevate as a result of the pads’ smaller floor space, which leads to a better PSI (Kilos consistent with Sq. Inch) being created.

- Traction: The lugs permit for remarkable traction on very slippery rainy clay slopes, the place even going uphill with a delicate drum could be a fight.

- Layer Integration: The dimples left through a padfoot curler are a very good ‘key’ for the highest layer to stick to.

Running Ways for Most Density

Running a padfoot curler comes to sure tactics that make sure that the bumps are in reality efficient of their paintings. What the operator does first is to look at carefully the walk-out segment.

When a brand new layer of soil in its unfastened state is laid down, the pads of the curler will have the ability to penetrate deep into the fabric. Because the soil compacts from the bottom-up and the drum reaches the outside, the pads will penetrate much less and not more. The curler will ultimately “stroll out” of the soil through touring at the tip of the pads.

That is a technique that the operator can know that the layer has been sufficiently compacted. Additionally, the operator will have to now not fail to remember the rate issue; if you happen to move too speedy, the pads won’t have the time to completely penetrate and knead the soil; however, going too gradual would possibly lead to over-compaction, which might if truth be told result in the soil construction being damaged.

- Tracking “Stroll-Out”: The operator can track the expanding top of the drum at the floor, which is the indication that the lowest layers are totally compacted.

- Pace Control: For vibratory programs and pads to have sufficient stay time to control the clay, a gradual and stable tempo (generally 2-3 mph) is the most efficient one.

- Trend Overlap: To forestall any ‘uncompacted soil’ streaks from final between the pad rows, the operator will have to overlap the passes through a minimum of one-third of the drum width.

Repairs and Put on of the Drum Lugs

The bumps on a padfoot curler aren’t best subjected to abrasion and have an effect on but in addition require repairs for the device to stay appearing smartly. With time, repeated operating in abrasive soils results in the pads’ top and form being wiped out. When the pads are brief and rounded, the portions of the pads can not move deep into the soil to combine it like ahead of, so the impact of the drum is best pseudo-smooth.

However, sticky clay may clog the pads so closely that it’s unattainable to split one from the opposite. Due to this fact, the drum could be like a forged cylinder of dust, and the pad’s penetration energy could be nonexistent. According to this put on downside, the huge scraper bars are actually being fitted on fashionable padfoot rollers.

Those are metal blades situated across the drum that, in some way, act because the exterior palms of the drum, which blank the dust off the drum all the way through all the revolution.

- Scraper Bar Adjustment: Right kind adjustment of the scraper bars is completed such that they’re saved in very shut proximity to the drum floor in an effort to save you subject matter build-up between the pads.

- Pad Recovery: Previous pads might be mounted through re-welding or converting to new ones of the geometric form, measurement, and penetration intensity that that they had firstly.

- Hydraulic Well being: Padfoot rollers paintings in opposition to resisting forces which are very top. Due to this fact, the hydraulic motors need to take care of in reality top so much and so widespread assessments of each the fluid and filters are important.

Programs and Challenge Suitability

The padfoot curler could be very a lot the primus inter pares of heavy earth-moving and infrastructure tasks. You would not usually in finding it paving your house’s driveway, however relatively it is going to be nearly in all places on monumental civil engineering websites. As an example, they play a an important function in earthen dam development, the place the clay core will have to be watertight as a result of just a only a few ft of separation exist between the general public and the water.

The similar is correct of landfill development, the place they’re used to compact waste and clay liners as a way to save you the leaching of hazardous components into the groundwater. In freeway development, those rollers are used within the preparation of the sub-base, i.e., the deep herbal soil that lies below the gravel and asphalt.

With out the deep compaction {that a} padfoot curler is able to, the freeway above could be matter to buckling because the clay below it settles or shifts with moisture adjustments.

- Water Retention Constructions: Their use is indispensable at dams, levees, and reservoirs to stay the permeability of the soil at a minimal via dense compaction.

- Highway Subgrades: In an effort to stabilize herbal flooring ahead of laying any mixture or pavement on it.

- Trench Backfilling: Smaller, remote-controlled trench rollers (generally having padfoot drums) are used to soundly compact soil in deep software trenches.

FAQs

What differentiates a padfoot from a sheepsfoot curler?

The latter is a static device with cylindrical legs and is basically used for semi-cohesive soils. A contemporary padfoot curler has geometric pads which are usually tapered and is made to make use of vibratory pressure, which makes it simpler in extremely cohesive clays and likewise compact quicker and with extra pressure.

Can a delicate drum be efficient on clay soil?

You will have to without a doubt now not check out that, as a delicate drum will probably be vulnerable to “bridging” over cushy spots commonplace in clay whilst forming a troublesome layer on most sensible, thus sealing the outside with out compacting the sublayers. The outcome will probably be settling in a while. In an effort to eliminate air wallet and moisture and stage off the basis, the padfoot curler must penetrate and knead the clay.

What’s a steam curler with bumps known as?

Technically talking, a “steamroller with bumps” is a padfoot curler or tamping curler. A very long time in the past those had been sheep’s foot rollers. On the other hand, within the trade they’re referred to as “padfoots” or soil compactors with a padfoot shell equipment.

What’s the function of a padfoot curler having bumps?

The bumping or pad-shape function is going deep to the soil floor; penetration and compaction is thus performed from the lowest up layer. Listen the curler’s weight into small spaces (the guidelines of the pads), which promotes the drive so top that it breaks the bonds of the sticky soil debris and pushes them in combination.

What number of rounds will have to a padfoot curler do?

There’s no particular resolution to the query because the choice of passes relies basically at the soil kind and moisture content material, however most of the time of thumb, it’s mentioned {that a} padfoot curler wishes 4 to eight passes to reach the required density. The motive force/operator usually appears out for the device to “stroll out” of the soil; this example refers back to the pads not sinking deep into the soil indicating the soil being compacted.

Can a padfoot be used on asphalt?

A padfoot curler is absolutely the no faire on a floor this is asphalt. The steel pads would be the ones to rip aside the smoothness of the asphalt. Puncturing it and breaking the pavement structurally would be the finish outcome. Clean drum or pneumatic tire rollers are those that can be utilized for asphalt compaction.

Which is the most efficient curler for rainy grime?

The Padfoot curler is most suitable for rainy, clinging grime. Pads can input and go out a rainy soil with out being trapped through the device because of their form. On most sensible of that, the kneading procedure is helping the soil floor space to be extra uncovered and subsequently aids the drying out of soil.