If you happen to personal or continuously haul a trailer, you realize that the wiring and electric device is its lifeline. With out correctly operating lighting fixtures, flip indicators, and brakes, your trailer isn’t simply unsafe, it’s unlawful to perform at the street. But, trailer wiring issues are some of the maximum not unusual trailer problems homeowners face. They are able to creep up abruptly, frequently on the maximum inconvenient occasions: proper earlier than a protracted go back and forth, whilst hauling at night time, and even whilst you’re attached at a hectic activity web page.

On this information, we’ll take a deep dive into {the electrical} device of trailers, the commonest issues of trailer wiring, tips on how to troubleshoot them, and tips about tips on how to repair trailer wiring so your rig runs reliably.

Why Trailer Electric Programs Are So Inclined

Not like the secure wiring in a car’s frame, trailers are uncovered to harsh prerequisites. Call to mind the whole thing your trailer faces: street salt in wintry weather, water splashes on wet days, warmth in summer time, mud on gravel roads, consistent vibrations from towing, or even unintended harm all over loading or unloading. Over the years, those components put on down insulation, corrode connectors, and motive wires to loosen or damage, all of which result in trailer electric device issues.

Including to the problem, trailers frequently use a flat 4-pin or 7-pin connector device. Whilst those are standardized, they depend on cast electric continuity between truck and trailer. Even a tiny quantity of rust, a unethical prong, or a susceptible flooring twine could cause issues of trailer electric techniques, corresponding to flickering or failing lighting fixtures.

The Fundamentals of a Trailer’s Electric Machine

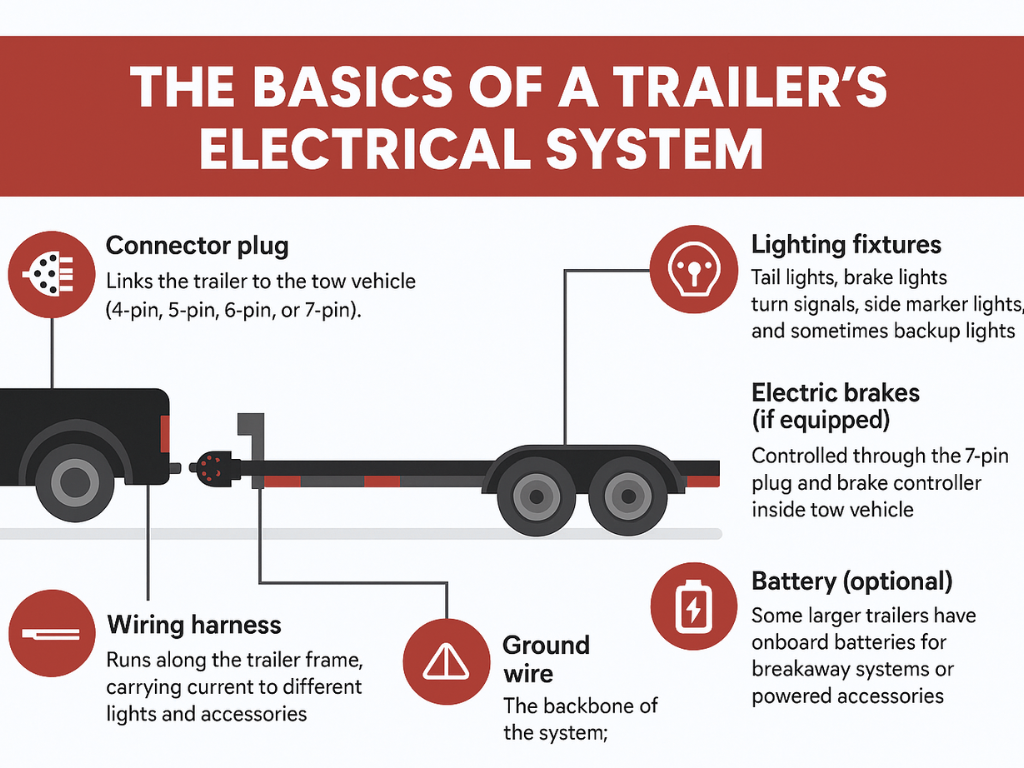

Prior to leaping into trailer electric device issues, it is helping to understand the fundamentals of ways a trailer’s wiring works:

- Connector plug: Hyperlinks the trailer to the tow car (4-pin, 5-pin, 6-pin, or 7-pin).

- Wiring harness: Runs alongside the trailer body, sporting present to other lighting fixtures and equipment.

- Flooring twine: The spine of the device; and not using a cast flooring, not anything works constantly.

- Lights: Tail lighting fixtures, brake lighting fixtures, flip indicators, facet marker lighting fixtures, and now and again backup lighting fixtures.

- Electrical brakes (if provided): Managed throughout the 7-pin plug and brake controller within the tow car.

- Battery (non-compulsory): Some higher trailers have onboard batteries for breakaway techniques or powered equipment.

When any such elements fails, it frequently ends up in issues of trailer electric techniques that require fast consideration.

Commonplace Trailer Wiring and Electric Issues

1. Lighting fixtures No longer Running at All

If each and every gentle is out, the problem generally lies on the connector. A free plug, corroded pins, or blown fuse within the tow car are most likely culprits. In some instances, the bottom twine could also be disconnected or rusted away, a vintage instance of issues of trailer wiring.

2. One Serve as No longer Running

If brake lighting fixtures paintings however flip indicators don’t, the problem is generally remoted to a particular circuit. A damaged twine, unhealthy bulb, or corroded socket could also be in charge.

3. Dim or Flickering Lighting fixtures

This frequently signifies a deficient flooring connection. Since trailers depend on a unmarried flooring twine, any rust or looseness the place it attaches to the body could cause susceptible present drift and routine trailer wiring issues.

4. Brakes No longer Attractive

For trailers with electrical brakes, wiring problems are not unusual. A inaccurate brake controller, damaged blue twine (which carries brake sign), or corroded connection can save you the brakes from activating, growing critical trailer electric device issues.

5. Brief Circuits & Blown Fuses

Frayed wires rubbing towards the trailer’s metallic body frequently result in brief circuits. This no longer handiest blows fuses however too can soften wires or motive sparks, a perilous downside with trailer electric techniques if left unaddressed.

6. Corrosion in Connectors

Moisture, street salt, and common publicity corrode the metallic contacts within the plug. Even a gentle greenish buildup can block electric present, resulting in intermittent operation and irritating issues of trailer wiring.

Troubleshooting Trailer Electric Issues

Diagnosing trailer wiring issues doesn’t must be intimidating. Right here’s a step by step procedure you’ll be able to practice with only a multimeter and a few persistence:

- Get started on the connector. Take a look at that it’s absolutely seated, freed from rust, and that each one pins are instantly.

- Check the tow car. Plug in a tester or use a multimeter to verify the truck is sending the right kind indicators.

- Take a look at the bottom. Search for a blank, tight flooring connection between the trailer body and wiring.

- Paintings down the harness. Observe the wires alongside the body, in search of cuts, burns, or pinches.

- Check up on bulbs and sockets. Take away the lens covers and make sure the bulbs are intact and seated appropriately.

- Check continuity. With a multimeter, take a look at for present drift throughout wires suspected of being inaccurate.

Via following those steps, you’ll temporarily discover ways to repair trailer wiring and deal with many not unusual issues of trailer electric techniques earlier than they irritate.

Preventative Repairs for Trailer Wiring

Like all device, prevention saves extra complications than maintenance. A couple of small conduct can dramatically cut back trailer wiring issues:

- Use dielectric grease on connectors to dam moisture and corrosion.

- Safe wires tightly alongside the body with clips or loom to forestall rubbing and chafing.

- Blank plugs continuously, particularly after wintry weather using.

- Take a look at grounds frequently, making sure naked metal-to-metal touch.

- Duvet connectors with a weatherproof cap when no longer in use.

- Exchange broken wiring as an alternative of patching with tape, warmth shrink tubing, or weatherproof connectors are higher.

Constant care is probably the most dependable means of figuring out tips on how to repair trailer electric techniques earlier than problems result in pricey breakdowns.

When to Name a Skilled

Some problems are easy to fix, however others, particularly involving brakes or breakaway techniques, would possibly require a certified. If you happen to’ve attempted troubleshooting and the problem persists, or if you happen to’re noticing common fuse blowouts, it’s very best to have a professional carry out a complete inspection. Sure issues of trailer wiring or issues of trailer electric techniques require complicated checking out apparatus and enjoy to unravel appropriately.

Stay Your Trailer Protected with Our Provider & Restore

Trailer wiring issues and trailer electric device issues are greater than minor inconveniences, they may be able to temporarily become roadside breakdowns, pricey tickets, and even unhealthy injuries. At 4 Winds Trailers, we understand how vital it’s to stay your trailer in best situation. That’s why our professional group gives whole inspection, diagnostics, and service services and products to catch problems earlier than they grow to be main complications.

From inaccurate connectors and corroded plugs to complete wiring replacements, we’ve got the enjoy and portions readily available to maintain all of it. Our store shares high quality wiring kits, sturdy connectors, and lights techniques designed to stay your trailer road-legal and loyal.

Don’t let issues of trailer wiring or a failing electric device stay you off the street. Believe 4 Winds Trailers for dependable carrier, rapid maintenance, and the portions you want to haul with self belief.