Your CTL (Compact Monitor Loader) will depend on the overall force motors to stay it working. When a last force fails, prices come with restore/substitute and dear downtime. Extending the helpful lifetime of your ultimate drives reduces downtime and service prices, that means a greater benefit margin and extra productiveness.

On this Store Communicate weblog put up, we’ll take a look at guidelines for extending the lifetime of CTL ultimate drives, specializing in upkeep and inspection, running practices, and monitor pressure and alignment.

Listed here are a couple of different Store Communicate weblog posts you could to find helpful:

Tip #1: Make Repairs and Inspection a Precedence

Practice the producer’s really useful upkeep time table to verify right kind lubrication and determine attainable issues early. We suggest checking your tools oil ranges about each and every 100 hours of operation and converting the tools oil once or more a 12 months. If you must stay topping off the tools oil whilst you take a look at the degrees, you’ve gotten a leak that should be addressed. And in case your tools oil is nasty whilst you alternate it, it must be modified extra continuously.

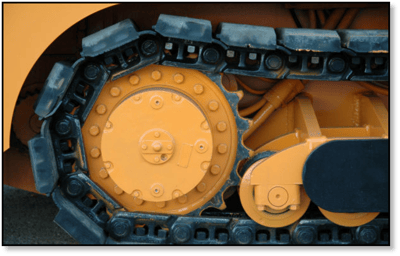

Additionally, incessantly examining the overall force is a good suggestion. Take a look at for leaks, broken seals, and cracks within the hub. In any case, stay the outside of the overall force and undercarriage blank by means of getting rid of dust and particles that may get packed across the force motor and doubtlessly injury mechanical face seals. By no means forget about a leaking seal as it lets in contamination to go into and significant fluids to leak out. Leaks don’t ever recover – they simply worsen.

Tip #2: Use Business Highest Running Practices

Repairs isn’t the one method to prolong the lifetime of your ultimate force motor. Mavens counsel that you simply reduce spinning and counter-rotating. Turning with three-point turns reduces tension at the ultimate force and tracks. Surprise a lot may also be problematic: easy operation, sluggish acceleration, and deceleration offer protection to the force elements. Mavens additionally say prime speeds build up put on and tear at the force gadget, so decrease speeds must be used when imaginable.

It’s additionally a good suggestion to, when imaginable, commute on company, stage surfaces: Over the top tension on asymmetric terrain can put on the overall force in advance. Then again, we all know that isn’t all the time possible for some varieties of packages.

Tip #3: Deal with Monitor Stress and Alignment

Keeping up right kind monitor pressure is very important in your tracks and ultimate drives as a result of over-tightening can injury the overall force. If the tracks to your device are too tight, it could reason the overall force motor to look susceptible.

Misaligned tracks additionally pressure the overall force, so take a look at alignment incessantly. We suggest adjusting the monitor pressure and alignment in line with the producer’s directions in the event that they’re to be had.

Some Further Guidelines

Imagine making an investment in undercarriage coverage. Guards and shields can lend a hand save you injury from particles and rocks. Steer clear of storing your CTL long-term in excessive temperatures or harsh prerequisites when imaginable. And all over the iciness months, don’t let ice increase at the monitor: now not best is it heavy, however water expands when it freezes.

Conclusion

Your ultimate force motors stay your CTL shifting, and the longer their lifespan, the extra prices you’ll save in restore and downtime. We are hoping you’ve discovered the following pointers useful, and you probably have any questions on Ultimate Power motors, touch us at Texas Ultimate Power Motors.