Trusses are an integral part of your post-frame development. You may really feel extra relaxed along with your development procedure after understanding a couple of info about them.

We all know that no longer all trusses are made the similar, and that’s because of their versatility.

A pole barn roof truss accommodates more than one elements, together with a most sensible chord, backside chord, inner internet individuals, and metal connector plates.

On this article, we’ll speak about the most typical sorts of trusses used to construct pole barns.

The Maximum Not unusual Pole Barn Trusses

1) Truss Varieties

On the subject of trusses, there are fairly a couple of tactics they may be able to be assembled and constructed. The webbing inside of each and every body may also be designed otherwise. To reinforce extra sq. photos, some trusses should be constructed higher. The 3 trusses we’ll speak about under make up 99% of the trusses used within the post-frame business.

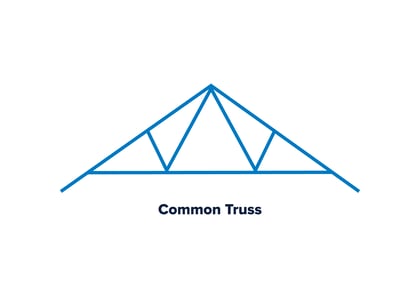

Not unusual Truss

Let’s get started by way of discussing a not unusual truss, also known as an ordinary truss. This truss is completely symmetrical; it has a height on the middle and the similar pitch and heel on either side.

The pitch refers back to the perspective at which the truss slopes or inclines. Pitch is the most important design part as it determines the stableness of the roof construction.

The heel is on the finish of the truss or close to the ground. This part additionally is helping to offer balance, supporting the entire truss device.

Other trusses are for use on one task, relying on architectural necessities. A normal truss is most often used for structures with same old roof designs.

If we imagine pricing, a not unusual truss has a tendency to be the least pricey possibility.

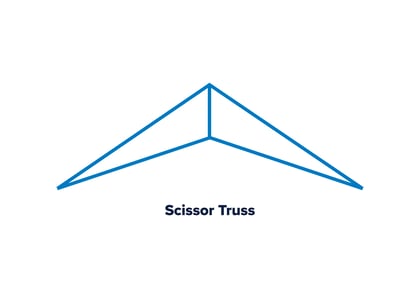

Scissor Truss

Whilst an ordinary truss has a horizontal most sensible and backside chord, a scissor truss has a sloping most sensible and backside chord.

Because of their distinctive design, scissor trusses are very structurally sound. Their weight is shipped lightly all the way through the construction for the reason that sloping most sensible and backside chords meet on the middle.

Scissors trusses are normally engineered to satisfy particular load necessities, improving their structural integrity much more.

A scissor truss is frequently used for structures with vaulted ceilings, making an allowance for an open internal look. Even with a visually interesting aesthetic, the roof device’s structural integrity isn’t compromised.

Scissor trusses have a tendency to be somewhat dearer because of their higher chords.

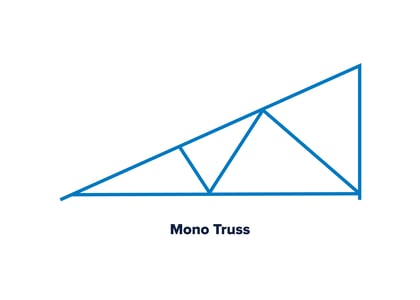

Mono Truss

Mono trusses may also be present in structures with a one-sided roof, like lean-tos. Because of their objective, mono trusses slope in just one course. Call to mind this taste as “part” a not unusual truss.

In sure situations, mono trusses can range in pitch peak. “Vaulted mono” trusses are used for multi-level roof strains or vaulted ceilings.

General, their easy design lets in for a very easy set up, making them an economical resolution. Mono trusses are a super possibility if you wish to upload on or construct a lean-to.

When taking a look at pricing, a mono truss is analogous to a not unusual truss. Even though, if the mono truss has a low pitch, it might be two times as pricey.

Different

There are different truss types, however they are much less not unusual within the post-frame business. Different sorts of trusses come with:

2) Logistics

In case you’re curious in regards to the truss manufacturing procedure, have a look at the back of the scenes. The design, manufacturing, and transportation of trusses to a task web site are all a part of the method.

Design

Trusses are designed by way of professional engineers who’ve years of training and revel in. The engineer targets to make a structurally sound truss device with right kind roof reinforce.

Engineers also are chargeable for calculating load capacities and settling on suitable fabrics. They play a the most important function within the post-frame business by way of offering technical steering and a top point of talent in truss design.

Manufacturing

As soon as an engineer’s blueprint has been finalized, trusses may also be put into manufacturing. With the assistance of an assembler, an meeting line is put into position, making an allowance for the next steplaystation to be finished:

- Set forums into position

- Position gusset plates on most sensible and backside of trusses

- Use a hammer to set gusset plates

- Use a roof tracker; placing over 10,000 lbs of drive on gusset plates

- Permit for the steel arm to pick out up trusses; sliding trusses onto a curler

- The completing curler makes use of 13,000 lbs of drive at the truss

- Trusses transported to the stacker and looked after

Transportation

Upon transportation, trusses are saved within the backyard till in a position. The transportation procedure calls for considerate attention, and components like truss measurement and weight, course making plans, and right kind securing of fabrics are vital.

In-house dispatchers and drivers are chargeable for successfully handing over fabrics to a task web site.

As soon as all fabrics are procured, trusses are delivered without delay to the task web site. Framing carpenters can then start your post-frame development undertaking.

3) Pricing

Relating to pricing, the 4 major components that may have an effect on truss pricing are span, spacing, truss loading, and roof pitch. The truss types (not unusual, scissor, mono) have much less affect.

Normal Specifications

In most cases talking, the elements of a not unusual truss permit it to be essentially the most cost-effective form or possibility. When the use of the average truss as a baseline for worth comparability, we will see how different trusses would possibly evaluate:

| Truss Sort | Price vs Not unusual Truss | Reasoning |

|

Scissor Truss |

20% – 40% dearer |

Higher chord sizes; further webs |

|

Low Pitch Mono Truss |

50% dearer |

Higher plate sizes; frequently deeper heel |

|

Steep Pitch Mono Truss |

An identical |

Can make the most of an identical chords |

|

Parallel Chord Truss |

2x dearer |

Further webs because of the field form |

|

Attic Truss |

2x – 3x dearer |

In most cases 2-ply or extra |

|

Gambrel Truss |

60% – 110% dearer |

Further chords wanted for double pitch |

Subject matter Prices

It’s conceivable to peer the price of fabrics upward push and fall. Emerging subject material prices would possibly result in price range overruns, while falling prices may give cost-saving alternatives. Marketplace components are merely one thing to imagine. Useful saving guidelines would possibly come with:

- Tracking marketplace traits

- Maintaining a tally of components like provide and insist

- Accounting for charge fluctuations

- Timing your acquire with gross sales and promotions.

Which Form of Residential Publish Body Construction Will You Make a selection?

In the end, there’s a special form of residential pole barn for each and every individual’s taste. Imagine designing your pole barn on-line to peer what most closely fits you!

Able to take your next step within the development procedure? Please name us at (800) 552-2981 or achieve us on-line to resolve your pole barn estimate.

Do you wish to have to understand in case your thought is value pursuing? You’ll be able to request a coarse ballpark quote with out 100% committing to a post-frame undertaking.

Do you’ve extra questions on pole barn trusses that aren’t lined on this article? If you wish to have assist designing and making plans, please touch FBi Structures at 800.552.2981 or click on right here to e-mail us. In case you are in a position to get a value, click on right here to request a quote, and a member of our Buyer Engagement Staff will assist you to resolve the following steps of your undertaking.