New Delhi, February 10, 2026: The Car Part Producers Affiliation of India (ACMA), in collaboration with Boston Consulting Crew (BCG), lately launched a joint learn about titled “Bolts, Bytes and Bots: Reimagining Subsequent-Gen Auto Part Production in India”, which examines how digitalisation, automation and complicated analytics are reshaping India’s auto element production panorama.

The learn about comes at a defining second for the trade. Having grown at ~14% CAGR over the past 5 years to achieve just about USD 80 billion, the Indian auto element sector is concentrated on exports of USD 100 billion by means of FY30. As international OEM expectancies upward thrust on high quality, traceability, velocity and sustainability, the learn about unearths that Good Manufacturing facility adoption is not non-compulsory however central to competitiveness and international integration.

Commenting at the learn about, Vikrampati Singhania, President, ACMA, stated “The findings obviously point out that Good Manufacturing facility tasks are transferring from experimentation to execution around the sector. The following section will have to focal point on scaling those efforts throughout crops and the provider ecosystem. This may occasionally require shared platforms, deeper partnerships and coordinated ecosystem construction, the place trade our bodies like ACMA can play a catalytic function.”

In accordance with an trade survey of vehicle element producers throughout segments and sizes, complemented by means of in-depth discussions with trade leaders and shop-floor groups, the learn about highlights a transparent shift in mindset – from remoted virtual pilots to enterprise-wide transformation.

Elaborating how digitalisation and automation are an crucial to be aggressive, Vinnie Mehta, Director Basic, ACMA, added, “What sticks out is the structural shift in how digitalisation is being seen not as a discretionary funding, however as a long-term lever for competitiveness. Because the trade balances export enlargement, coexistence of multiple-powertrains and team of workers demanding situations, sensible production gives a realistic pathway to strengthen reliability, productiveness and high quality the usage of present property.”

The learn about additionally notes that businesses adopting virtual and automation answers are already seeing tangible enhancements in operational visibility, high quality results, asset utilisation and responsiveness to buyer necessities.

Sharing point of view on what this shift approach for competitiveness, Vikram Janakiraman, Managing Director and Senior Spouse, BCG, famous that “India’s auto element sector has led the price on localization and import substitution over a few years, construction deep production capacity and scale. Nowadays, as enlargement hurries up throughout home and export markets, the problem is managing each quantity and complexity. It’s promising to look that the sphere has made a get started by means of adopting Good Manufacturing facility tasks, with Indian firms already understanding vital OEE enhancements, high quality features, and higher throughput from present property. Reimagining operations and provide chains, and construction factories of the long run, will probably be essential to unlocking the following wave of productiveness and competitiveness for the sphere.”

The ACMA–BCG joint learn about obviously underscores that Good Manufacturing facility adoption is rapid turning into a core capacity for Indian auto element producers as they combine deeper into international price chains and get ready for the following section of enlargement.

Reflecting on what it takes to make this transition paintings within the Indian context, Saurabh Chhajer, Managing Director and Spouse, BCG, stated, “For auto element producers in India, Good Manufacturing facility good fortune is dependent upon getting 3 issues proper in combination. First, mixing confirmed international applied sciences with India’s power in frugal, shopfloor-led innovation. 2d, sustained senior management sponsorship to push past pilots and deal with trade resistance. 3rd, a pointy focal point on basics: how firms consider information, how they construct virtual talents, and the way they organize trade in shopfloor techniques of running right through deployment. Those alternatives will in the long run resolve whether or not virtual tasks create lasting price or stay fragmented interventions.”

Key Findings from the ACMA–BCG Joint Learn about:

- The Indian auto element trade has grown at ~14% CAGR between FY20–FY25 to achieve ~USD 80 billion, with exports emerging 1.5x to ~USD 23 billion and ambitions of USD 100 billion by means of FY30.Over two-thirds of surveyed firms are already in pilot, scale-up or absolutely built-in levels of Good Manufacturing facility implementation.

- Just about 60% of businesses document moderate-to-transformational advantages, together with upper productiveness, stepped forward high quality, higher asset utilisation and quicker factor solution.

- Corporations that experience moved past pilots to scaled deployment are over 2x much more likely to look sturdy industry affect.

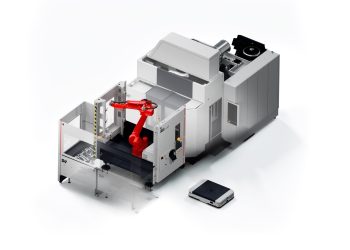

- Era adoption is progressing from IoT and connectivity to complicated analytics, AI-based predictive repairs, virtual twins and automation.

- Operations and high quality emerge as the highest priorities for virtual intervention, with provide chain, NPD and ESG as the following frontiers.

- Blank, system-generated information and interconnected virtual stacks considerably outperform remoted level answers.

- Virtual readiness is an increasing number of a prerequisite for international OEM sourcing because of emerging expectancies on traceability, audit readiness and zero-defect high quality.

About ACMA: The Car Part Producers Affiliation of India (ACMA) is the apex frame representing the pastime of the Indian Auto Part Business. Its club of over 1064 producers contributes greater than 90% of the automobile element trade’s turnover within the arranged sector. In FY2025, the blended turnover of the Auto Part Business stood at USD 80.2 billion with USD 22.9 billion in exports and a business surplus of USD 500 million.