For part a century, system bases fabricated from Granitan® have shaped the basis for dependable STUDER precision in cylindrical grinding.

There’s a centered operating surroundings as staff in overalls in moderation get ready the mould: they set up pipes, cables, plates, threaded dowels, and rails. Then a formidable system pours within the viscous combination, which is blended in line with a intently guarded recipe, with more than a few sizes of mixture. It is a mineral casting combination that can harden right into a high-performance system base in not up to an afternoon. For fifty years, this composite subject matter, Granitan®, has been the basis for the famend accuracy and reliability of STUDER cylindrical grinding machines.

“It used to be a groundbreaking innovation in system device production when the RA5, the primary series-produced cylindrical grinding system with a Granitan® system base, used to be introduced in 1976,” says Lennard Vorwerk-Handing, building engineer at STUDER. The iron-based grey cast-iron that used to be repeatedly used till then may most effective be shaped at very excessive temperatures and required intensive remodeling. Granitan®, however, can also be formed at room temperature, very similar to concrete. If truth be told, some producers had in the past experimented with cement-based system bases. “Cement-bound concretes show off considerably higher shrinkage and have a tendency to take in moisture. This intended that the desired absolute long-term balance may no longer be accomplished,” explains Vorwerk-Handing.

Top-performance Subject material With Many Benefits

After all, the advance staff of mavens from STUDER and a number of other spouse organizations got here up with the decisive thought: as a substitute of cement, epoxy resin used to be used as a two-component binder this is solid in the longer term and does no longer take in water. The mineral casting subject matter, christened Granitan®, used to be appropriate for precision portions and may be molded temporarily and successfully in-house. With out time-consuming post-processing, it may be used to fabricate near-net-shape system elements and combine constructions and contours immediately into the mould within the chilly casting procedure. In comparison to grey cast-iron, the extra energy-efficient production procedure additionally has a good impact at the sustainability stability of all the system.

Granitan® additionally revolutionized precision within the grinding procedure. One in all its remarkable benefits is its damping conduct, which is set fifteen occasions higher than that of grey cast-iron. Vibrations are temporarily absorbed through the fabric. “It is because the touch surfaces between the rock grains and the binder matrix successfully destroys the vibration calories,” explains Vorwerk-Handing. That is specifically vital in precision cylindrical grinding, the place even the smallest vibrations may end up in floor marks. Due to Granitan®, STUDER consumers succeed in upper product high quality and will function the precision cylindrical grinding machines with out particular foundations.

Granitan® is Repeatedly Being Optimized

The phenomenal thermal homes of Granitan® are not any much less vital. In comparison to grey cast-iron, it may possibly take in two times as a lot warmth calories earlier than the temperature adjustments through one stage Celsius. Warmth may be transferred as much as 13 occasions extra slowly within the system base On the similar time, it has a an identical growth conduct to metal or iron, because of this that no stresses happen on the coupling issues to steel system portions. The benefits for purchasers are huge: Granitan® is powerful in opposition to the temperature fluctuations which might be commonplace in on a regular basis manufacturing in manufacturing unit halls and permits reproducible grinding precision even in rooms that aren’t exactly air-conditioned.

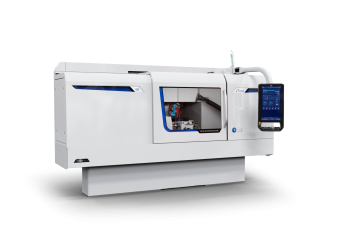

Fashionable STUDER cylindrical grinding machines are high-tech methods with intensive virtual features, delicate sensor era, and automation and networking options. Then again, Granitan® continues to be the system base hat supplies the precision and reliability for which the normal Swiss corporate with over 113 years of historical past is understood. The cause of that is steady optimization and extra building: These days’s Granitan® is the results of extensive analysis and building actions in subject matter composition and production era. Since 2009, STUDER has been production its Granitan® system bases as a part of a three way partnership with Schneeberger in a extremely specialised manufacturing facility in Cheb, Czech Republic – nonetheless the usage of its personal STUDER recipe and procedure keep watch over.

As well as, there at the moment are Granitan® recipes for explicit packages: The bottom combination S103 paperwork the forged, extremely damping system base, whilst fine-grained particular combinations are used for casting precision elements. Granitan® era thus permits the high-precision manufacture of StuderGuide® guideways with micrometer accuracy within the corporate’s personal molding store. The giant design freedom presented through the liquid subject matter all the way through preliminary forming leads to extremely compact and maintenance-friendly system designs that may no longer be conceivable with different production strategies.

A Strong Basis for the Long term

5 many years after its marketplace release, Granitan® has turn out to be synonymous with a solid system base that continues to set requirements within the business these days. Blended, the benefits for purchasers result in upper workpiece high quality, extra dependable manufacturing, and longer provider existence. In view of the rising calls for for precision, sustainability, and versatility, it due to this fact stays an indispensable foundation in machining, whether or not for system gear, aerospace, electronics, or clinical era.

To verify the ongoing luck of its consumers, STUDER is continually making an investment in optimizations and new options. One thrilling prospect for the long run, for instance, is the prospective integration of sensor era and electronics immediately into the system base which is conceivable because of the chilly casting procedure. “Granitan® is greater than only a subject matter; this is a era equipment and a platform for long term inventions,” says Rolf Grossenbacher, Gross sales Supervisor A ways East, including: “Our high-performance subject matter Granitan® will proceed to assist consumers carry out grinding on the chopping fringe of technological feasibility with STUDER machines.”

The Benefits of Granitan® at a Look

- Very good damping for prime grinding precision

- Thermal balance for constant effects

- Reproducible manufacturing of micrometer-precise guideways

- Longer device existence

- Speedy availability

- Extra sustainable production in comparison to grey cast-iron