Entire Information to Street Curler Machines: The best way to Use Them for Highest Street Building

Have you ever thought of how roads turn into so even and compact? The device used to reach this is known as a street curler gadget. Regardless of in case your challenge is a driveway, parking house, or street, realizing the right kind manner of the use of a street curler will also be the issue that makes the primary floor nonetheless excellent after ten years, whilst the opposite one will get cracks after only some months.

I will be able to give an explanation for to you all of the main points that it’s important to know when the use of this essential heavy apparatus.

What’s a street curler gadget?

A street curler (additionally named a compactor or steamroller) is a heavy engineering gadget, which is used to press asphalt, soil, gravel, or concrete within the strategy of street making. Merely put, it is a massive steel factor that flattens and compacts the earth or some other subject matter to make a company and long-lasting floor.

There are quite a lot of sizes and forms of those machines, corresponding to a tiny vibratory curler for a house driveway and an enormous three-wheel curler for a street.

Step 1: Make a selection the Proper Form of Street Curler

One factor that you simply will have to do earlier than beginning your engine is to select the right kind curler to your process. Those are those that you’ll choose between:

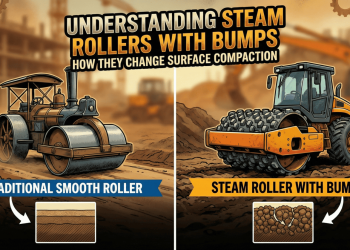

Clean Wheel Rollers: Are your only option relating to asphalt compaction and completing paintings. They’re those that produce the sleek floor that you simply see on highways.

Pneumatic Rollers: Have rubber tires as a substitute of metallic drums. Pneumatic rollers are your only option for asphalt sealing and making a watertight end.

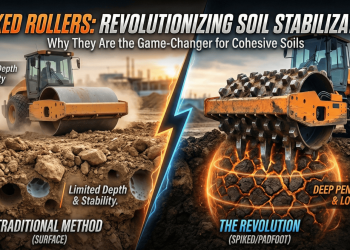

Vibratory Rollers: Generate the vibration that ends up in fabrics being compacted extra successfully. They’re your only option relating to soil compaction and granular base layers.

Tip from the sphere: A single-drum vibratory curler of 1-3 heaps will perhaps be the suitable selection for any residential paving challenge. Should you use a gadget this is too huge, you’re going to be risking the wear of the subgrade.

Step 2: Check up on Your Street Curler Sooner than Operation

Protection first! By no means skip your pre-operation inspection:

- Engine oil, hydraulic fluid, and gasoline will have to be checked for his or her ranges.

- The drum will have to be checked for any roughly injury, particles, or buildup.

- Tests will have to be made on all of the controls, brakes, and steerage thru checking out.

- It will have to be showed that the water spraying machine is operating (it’s used for fighting the sticking of the asphalt).

- The realm will have to be checked for any leaking hydraulic fluid and for unfastened bolts.

- Tire power will have to be checked on pneumatic rollers.

Actual-world tip: Stay a tick list within the cab. One operator I knew skipped checking hydraulic fluid and ended up with a $3,000 restore invoice when the machine overheated.

Step 3: Get ready the Floor House

Your curler is most effective as excellent as what you might be rolling over:

- Transparent the realm of labor of any particles, rocks, and unfastened subject matter

- Be certain that the bottom layer isn’t just correctly graded but additionally leveled

- Check up on the drainage slope for correctness (in most cases, a 2% grade minimal)

- Make certain that the fabric thickness meets the specified requirements.

- Do not fail to remember to test if the outside temperature is true (asphalt for compaction will have to be 175-225°F)

Actual-world tip: Use an infrared thermometer for asphalt paintings. Rolling too chilly manner deficient compaction; too sizzling and you can displace the fabric.

Step 4: Get started with the Correct Rolling Trend

That is the place revel in in point of fact counts:

For Asphalt Paving:

- Rolling will have to be achieved from the outer edges to the middle

- First of all, perform static (non-vibrating) operations at the floor of the recent asphalt

- Every of your passes will have to overlap the former ones by means of 6–8 inches.

- Make your first go inside 10 mins of paving when the fabric remains to be sizzling

For Soil Compaction:

- Start on the lowest level and transfer to the perfect

- Flip the vibration on with the first actual go.

- On granular fabrics, overlap by means of a minimum of 12 inches

- Attempt to paintings in immediately traces up to imaginable

Actual-world tip: At all times stay transferring. Preventing on contemporary asphalt creates depressions which can be just about unimaginable to mend later.

Step 5: Use the Proper Compaction Method

Right here is how you’ll succeed in most density:

Pace Issues: You will have to stay your curler transferring at a velocity of 2-3 mph for asphalt, and for soil, it will have to be fairly sooner (3-5 mph). If compaction is simply too rapid, you will not get the suitable density; if too sluggish, chances are you’ll push the fabric.

Choice of Passes: Asphalt most often calls for 3-5 passes, whilst soil would possibly want 4-8 relying at the thickness of the raise. With each and every passing, density will have to build up by means of 2–5%.

Vibration Settings: Top amplitude will have to be used for granular soils and base layers, and occasional amplitude for skinny lifts and constructions.

Tip from the actual global: You will have to take a look at your compaction by the use of a nuclear density gauge or an evidence curler. I’ve noticed contractors having to redo whole parking so much as a result of they idea that they’d accomplished the right kind density with out checking out.

Step 6: Pay Consideration to Downside Spaces

Sure spots want further care:

Edges and Joints: After putting the fabric, initially, roll the longitudinal joints. Alongside the perimeters the place the fabric is much less confined, make 2-3 further passes.

Close to Utilities: To steer clear of inflicting injury, lower or take away the vibration that is occurring inside 10 ft of underground utilities, development foundations, or manholes.

Transitions: Be moreover cautious when the brand new pavement goes to the previous one to verify the right kind bonding and that the elevation is matching.

Actual-world tip: At all times have a hand tamper or a plate compactor able for the tight corners and spaces the place your curler can not succeed in. Those puts are the spots of failure for those who take away them out of your attention.

Step 7: Observe Compaction Effects

You can not fortify what you don’t quantify:

- Follow for subject matter displacement or shoving (an indication that you’re rolling too sizzling or too aggressively)

- Seek for checking or hairline cracks (sign that rolling is simply too chilly)

- Read about for curler marks that don’t disappear (point out inadequate compaction)

- Make use of a immediately edge to substantiate smoothness

- Perform density checks as consistent with challenge necessities

Actual-world tip: {Photograph} and log your rolling trend and the collection of passes. In case there’s ever a query in regards to the high quality of labor, documentation is the solution to warding off complications.

Step 8: End with Ultimate Passes

The ultimate passes you are making are what exhibit the entire process to the sector:

- Do the ultimate passes with the vibration became off (breakdown rolling most effective)

- Ensure that no curler marks stay

- Ascertain that the outside seems to be the similar everywhere

- Test that the cross-slope and grade are right kind

- Have a look at the perimeters to peer if they’ve the suitable taper and are sealed

Actual-world tip: A couple of operators wish to do their ultimate go within the course of site visitors. It produces a minor texture that may build up skid resistance.

Step 9: Blank and Deal with Your Apparatus

Correct care will stay the apparatus in excellent situation longer:

- Take away asphalt build-up from the drum instantly (if essential, use diesel gasoline or a business liberate agent)

- Grease all fittings as consistent with the producer’s time table

- After the primary 50 hours of operation, take a look at and tighten the bolts

- If imaginable, stay the apparatus within to steer clear of rust

- Alternate the hydraulic filters on the periods which can be advisable

Actual-world tip: An unsoiled drum is the most productive drum. Asphalt buildup ends up in much less environment friendly compaction and would possibly decrease your gadget’s resale worth by means of a couple of thousand.

Not unusual Errors to Keep away from

Be told from others’ mistakes:

- Rolling too few passes: Now not sufficient compaction ends up in the outside no longer lasting very lengthy

- Inconsistent overlap: Could cause a strip of street this is susceptible and can crack first

- Fallacious temperature: That is the error that occurs probably the most when asphalt is being laid

- Ignoring climate: By no means compact if it is raining or if there’s frost

- Deficient conversation with the paving staff: Coordinate smartly with the staff for subject matter placement

Protection Issues for Street Curler Operation

Running heavy apparatus calls for consistent consideration to protection:

- At all times put on a high-visibility jacket, a security helmet, and steel-toed boots all the time

- If there’s a want to opposite, or paintings close to a street, then a spotter will have to be used

- Don’t use the gadget on slopes which can be greater than what is suggested by means of the producer

- Make certain that nobody is permitted close to the curler whilst it’s running

- Know the positioning of the underground utilities earlier than you do the compacting

- If the elements is sizzling then you definately will have to drink sufficient water and take breaks in order to not get drained

Fast Abstract

The usage of a curler gadget for roads successfully calls for:

- Opting for the easiest curler kind to your subject matter and paintings

- Doing detailed pre-operation assessments for protection

- Getting the outside able correctly earlier than compaction begins

- The usage of orderly rolling patterns from edges to middle

- Protecting the suitable velocity (2-3 mph) and overlap (6-12 inches)

- Making the right kind collection of passes (3-5 for asphalt, 4-8 for soil)

- Observing for bother spaces corresponding to joints, edges and transitions

- Measuring compaction density to substantiate the consequences

- Finishing the paintings with static passes to take away floor marks

- Cleansing and keeping up the apparatus after each and every use

Consistency and a spotlight to element are the primary components that can result in a a success street compaction. It’s not relevant in case you are making a brand new street or only a driveway; the right kind use of a curler is what is going to come up with a pleasant and long-lasting floor that can withstand the site visitors for years.

We will have to additionally indicate that the standard of the compaction is the primary affect at the pavement lifestyles out of just about all different components. So, be affected person, undergo those steps and you’re going to make surfaces that can ultimate for an extended time.