What does “clever production” imply to you, and the way is your company contributing to this modification?

For us at TaeguTec India, “clever production” isn’t only a buzzword; it’s about leveraging information and connectivity to reach remarkable ranges of potency, precision, and suppleness at the store flooring. It’s transferring past automation to a machine the place machines can be informed, are expecting, and optimize processes autonomously, minimizing waste and maximizing output.

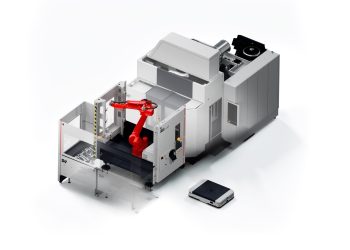

Our contribution to this modification is multifaceted. At first, our slicing equipment themselves are turning into smarter. We’re creating answers that combine with virtual tracking methods, offering real-time information on device put on, temperature, and function. This permits for predictive upkeep and optimized device lifestyles. Secondly, we’re actively concerned with collaborative tasks with gadget device developers and end-users to combine our tooling experience with their clever production platforms. This contains providing data-driven insights to give a boost to machining methods and general operational effectiveness. In the long run, we’re offering the “enamel” for clever production – the very important elements that at once have interaction with the workpiece, and making the ones enamel smarter.

Are you able to proportion a up to date step forward or initiative that helped empower your shoppers or channel companions in a vital means?

A vital initiative we’ve undertaken just lately, which has profoundly empowered our shoppers, is the growth and enhancement of our technical make stronger and alertness engineering services and products. In these days’s dynamic production panorama, it’s no longer sufficient to only promote a device; you wish to have to offer complete answers.

We’ve invested closely in coaching our utility engineers to be no longer simply product mavens, however problem-solvers who can paintings along our shoppers, examining their particular machining demanding situations and recommending optimum tooling and procedure parameters. This contains on-site make stronger, detailed technical seminars, and custom designed coaching techniques. A concrete instance could be serving to a buyer optimize their high-speed machining operations for a brand new subject matter, leading to a vital aid in cycle time and stepped forward productiveness. This direct engagement and data switch have constructed more potent partnerships and, crucially, empowered our shoppers to reach upper productiveness, at once impacting their final analysis. Our channel companions also are key beneficiaries, as they are able to leverage our enhanced technical experience to higher serve their very own buyer base.

How is your corporate embracing sustainability in machining – from fabrics to calories and lifecycle design?

Sustainability is an increasingly more essential facet of recent production, and at TaeguTec India, we’re dedicated to contributing definitely on this house. From a fabrics viewpoint, our center of attention is on creating longer-lasting and harder slicing equipment. This inherently reduces subject matter intake and waste generated from common device adjustments. We additionally conscientiously optimize our production processes to attenuate subject matter scrap and make sure effective usage of our uncooked fabrics, specifically tungsten carbide.

Relating to calories, our production amenities frequently assessment and undertake energy-efficient practices and applied sciences. This contains optimizing gadget usage, making an investment in additional energy-efficient apparatus the place possible, and exploring renewable calories choices for our operations in the long run.

Referring to lifecycle design, it’s about designing equipment that supply prolonged lifestyles and constant efficiency, thereby decreasing the total environmental footprint related to production. Whilst the direct recycling of our carbide equipment has its demanding situations because of the character of the fabric, we center of attention on maximizing the helpful lifetime of our merchandise and inspiring accountable disposal practices on the finish in their operational lifestyles, in step with native rules. Our number one contribution here’s making equipment that carry out longer, decreasing the will for brand new subject matter extraction and processing.

How do you notice virtual applied sciences (like AI, IoT, or virtual twins) redefining gadget device packages within the subsequent 3–5 years?

Virtual applied sciences will basically redefine gadget device packages within the subsequent 3–5 years, transferring us a lot nearer to really self sustaining and self-optimizing production.

- IoT (Web of Issues) will turn into much more pervasive. Each slicing device, each and every spindle, each and every gadget part will likely be attached, streaming real-time information on efficiency, put on, and environmental prerequisites. This huge quantity of knowledge would be the bedrock for additional developments.

- AI (Synthetic Intelligence) would be the mind that processes this IoT information. AI algorithms will analyze patterns to are expecting device put on, optimize slicing parameters for particular fabrics and geometries, or even establish doable gadget disasters earlier than they happen. This will likely result in extremely optimized machining processes with minimum downtime and most potency. We’ll see AI-driven adaptive regulate methods turning into common, mechanically adjusting feeds and speeds in keeping with real-time comments.

- Virtual Twins will likely be transformative. Believe a digital reproduction of a whole machining operation – the gadget device, the workpiece, and our slicing equipment. This virtual dual will permit for extremely correct simulations, enabling producers to nearly check other machining methods, optimize device paths, and are expecting results with precision earlier than a unmarried chip is reduce at the bodily gadget. This will likely enormously scale back prototyping time, subject matter waste, and result in first-time-right production.

At TaeguTec, we’re actively exploring how our slicing equipment can feed into those virtual ecosystems, offering the best information issues that AI and virtual twins wish to optimize machining efficiency.

Ability is a core motive force of future-ready production. How are you re-skilling or upskilling your team of workers for the brand new technology?

You’re completely appropriate; ability is paramount. The shift against clever production necessitates a team of workers with a unique ability set. We’re proactively addressing this via a multi-pronged way:

- Steady Coaching Techniques: We have now ongoing inside and exterior coaching techniques excited about complicated machining ways, new fabrics, and the virtual equipment related to our trade.

- Pass-Useful Finding out: We inspire our technical and gross sales groups to collaborate intently, making sure that our gross sales power understands the technical nuances and our technical groups are conscious about buyer demanding situations. This broadens their working out of your entire production ecosystem.

- Mentorship and Wisdom Switch: Skilled engineers and technicians mentor more recent workers, facilitating the switch of precious sensible wisdom and problem-solving abilities.

Our objective is to foster a tradition of constant finding out, making sure our workers don’t seem to be simply maintaining tempo with technological developments however also are provided to power innovation.

What values or management ideas information your decision-making in balancing innovation, industry enlargement, and social affect?

Our decision-making at TaeguTec India is guided through a core set of values and ideas, deeply ingrained in our organizational tradition.

At first, Buyer Centricity is paramount. Innovation and industry enlargement will have to in the end serve our shoppers, offering them with answers that actually give a boost to their productiveness and profitability. This implies listening carefully to their wishes and demanding situations.

Secondly, Excellence and Innovation. We’re dedicated to pushing the limits of slicing device generation. This idea encourages us to spend money on R&D, discover new fabrics and geometries, and undertake complicated production processes. We imagine that true enlargement comes from providing awesome merchandise and answers.

Thirdly, Integrity and Duty. This guides our movements in all facets, from moral industry practices to how we have interaction with our workers, companions, and the wider group. It guarantees that our pursuit of enlargement is sustainable and performed with the very best moral requirements.

After all, Lengthy-Time period Imaginative and prescient with Social Have an effect on. Whilst temporary industry enlargement is essential, we all the time perform with a long-term viewpoint. This contains spotting our position within the wider society. Our contribution to social affect comes from enabling effective and sustainable production for our shoppers, which in flip contributes to financial enlargement and activity advent throughout the nation. By way of offering the equipment that power business development, we not directly give a contribution to the country’s production prowess and general prosperity. We intention for a harmonious steadiness the place our innovation and enlargement additionally give a contribution definitely to the communities through which we perform.