The strategic acquisition, in the past introduced, is now whole. With the purchase of the GF Machining Answers Department of Georg Fischer AG, the UNITED GRINDING Workforce expands its portfolio to fifteen manufacturers. The brand new workforce operates below the title UNITED MACHINING SOLUTIONS and, with general gross sales of over USD 1.5 billion, has develop into some of the biggest device instrument producers on this planet.

With the takeover of the GF Machining Answers Department of George Fischer AG by means of the UNITED GRINDING Workforce, some of the biggest device instrument producers on this planet has emerged – with general gross sales of over USD 1.5 billion and round 5,000 staff at over 50 world places. The corporate was once renamed UNITED MACHINING SOLUTIONS and keeps its headquarters in Bern, Switzerland.

Stephan Nell, CEO of the brand new workforce and the UNITED GRINDING Workforce, finds: “There was a long-standing need to merge the 2 firms. Lead shareholders Rosmarie and Martin Ebner expressed their complete self belief on this strategically essential step inside the global of world device instrument production, authorizing the important capital building up to make this imaginative and prescient into truth. It’s uncommon for 2 firms to counterpoint each and every different in addition to UNITED GRINDING and GF Machining Answers. This is applicable no longer best to our product portfolios, our world alignment, and our figuring out of high quality, but in addition to the tradition and mindset of our staff. I’m satisfied that we will make a large distinction in combination, for the advantage of our shoppers.” The gang’s board of administrators intently monitored and supported the method. Fred Gaegauf, Chairman of the Board of Administrators on the UNITED GRINDING Workforce, famous: “The merger of those two firms has created a Swiss powerhouse in device instrument production.”

Optimum addition

With a presence in additional than 50 places, a complete product portfolio, and a complete of 15 main manufacturers of their industries, the root is laid for long run good fortune. “It’s the most efficient resolution shall we make,” confirms Ivan Filisetti, CEO of GF Machining Answers and a member of the brand new workforce’s Control Board. “Our merchandise don’t overlap; they supplement each and every different. This makes integration a lot more uncomplicated. And as a Swiss corporate, we proportion the similar tradition with a powerful dedication to innovation and digitalization. We will be able to additionally stay after our function of being the most popular spouse for our shoppers, at all times in a position with custom designed answers and complete experience – in different phrases, ready to provide a lot more than simply high-end machines. The gang is helping us with its sturdy world alignment, staff on website online at our shoppers’ premises, and our breadth of technological experience.”

In R&D, collaboration isn’t just advisable for the corporate and its shoppers within the building of cutting edge answers. Synergies may also be leveraged with reference to new requirements and rules, which can be turning into increasingly more essential and require device producers to reply as a way to stay their machines have compatibility for the long run.

The 2 firms are specifically hooked up by means of their shared Swiss roots and robust world alignment. “With greater than 50 places international, there are few device instrument producers which are as world as we’re and as on the subject of their shoppers,” believes Nell. “With the ability to talk the language of our shoppers and be offering speedy, competent give a boost to is the most important decision-making criterion for our shoppers. Our world staff proportion the similar roots and values,” provides Filisetti.

Because of many commonalities and an optimum addition to the portfolio, the necessities for effectively merging as UNITED MACHINING SOLUTIONS may just rarely be higher.

The gang will essentially provide itself to the outdoor global via its particular person manufacturers. “Someday, we need to additional give a boost to the identities of our manufacturers, which were recognized and anchored available in the market for a few years,” explains Nell. “The manufacturers have an extended custom, stand for the very best quality and are continuously pioneers of their box. Our shoppers agree with the manufacturers they’ve discovered to understand and recognize.”

UNITED MACHINING SOLUTIONS with two divisions and established control crew

The 2 divisions UNITED GRINDING and UNITED MACHINING fall below the umbrella title of the crowd, UNITED MACHINING SOLUTIONS. UNITED GRINDING comprises the manufacturers MÄGERLE, BLOHM, JUNG, STUDER, SCHAUDT, MIKROSA, WALTER, EWAG, and IRPD. With their experience within the applied sciences of floor and profile grinding, cylindrical grinding, instrument machining and additive production, they proceed to provide extensive utility wisdom, an in depth product portfolio, and a definite vary of products and services for the manufacture of high-precision parts.

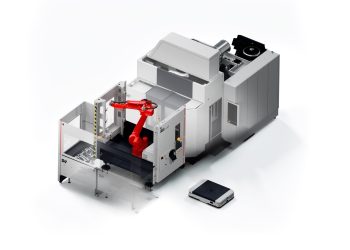

GF Machining Answers is without doubt one of the global’s main suppliers of precision engineering and complex production applied sciences for high-precision parts and tooling trade. Those competencies and applied sciences might be included into the brand new workforce within the UNITED MACHINING department. The gang’s portfolio might be expanded to incorporate the manufacturers AGIE CHARMILLES, CHARMILLES, MIKRON MILL, LIECHTI, STEP TEC, and SYSTEM 3R. This comprises machines for high-speed milling, EDM (Electric Discharge Machining), laser texturing, and laser micro-machining. As well as, the department gives cutting-edge spindles in addition to answers for automation and digitization, sponsored by means of world buyer and alertness give a boost to.

The control crew at UNITED MACHINING SOLUTIONS is composed of 4 other people with an extended historical past within the respective firms: Stephan Nell, Ivan Filisetti, Michael Horn, and Heinz Poklekowski. Stephan Nell, CEO of the UNITED GRINDING Workforce, has spent 22 years inside the workforce. He now takes over as chairman of the Control Board and strategic management for Gross sales and Buyer Care. Ivan Filisetti, President of GF Machining Answers and affiliated with the corporate for 23 years, is answerable for setting up the long-term imaginative and prescient of the brand new workforce’s era space and stays CEO of UNITED MACHINING. Michael Horn, who’s answerable for Operations and IT, brings his a few years of revel in in device instrument engineering and maximum not too long ago as a member of the Board of DMG MORI AG to the brand new workforce. And Heinz Poklekowski, who has been a bunch member for 35 years, his most up-to-date function being CFO for the UNITED GRINDING Workforce, will suppose duty for Finance and Workforce Services and products.

Premiere at EMO Hannover with 8 global firsts

The brand new workforce UNITED MACHINING SOLUTIONS will make its debut at EMO Hannover, the sector’s main business display for manufacturing era. For fifty years, the business display has equipped a novel platform each and every two years to realize a complete assessment of the trade’s world providing. The business display will happen from September 22 to 26 this 12 months. UNITED MACHINING SOLUTIONS might be represented by means of its 15 manufacturers and show off no fewer than 8 world-first inventions.

About UNITED MACHINING SOLUTIONS

With general gross sales of over USD 1.5 billion, UNITED MACHINING SOLUTIONS is without doubt one of the biggest device instrument producers on this planet. With round 5,000 staff at over 50 world manufacturing, provider and gross sales places, UNITED MACHINING SOLUTIONS is on the subject of its shoppers and extremely environment friendly.

The gang is arranged into two divisions: UNITED GRINDING and UNITED MACHINING.

UNITED GRINDING comprises the manufacturers MÄGERLE, BLOHM, JUNG, STUDER, SCHAUDT, MIKROSA, WALTER, EWAG and IRPD. Its applied sciences come with floor and profile grinding machines, cylindrical grinding machines, machines for instrument machining and device gear for additive production.