A unexpected hydraulic line blowout is extra than simply an inconvenience—it may possibly close down your jobsite, prolong your challenge, and price you in misplaced time and fluid cleanup. Whether or not you’re an impartial contractor depending on a unmarried system or a condo industry seeking to steer clear of buyer lawsuits, working out how and why blowouts happen is very important.

This Store Communicate Weblog submit is not going to most effective permit you to acknowledge the dangers, but in addition empower you to identify the caution indicators early and take easy steps to forestall crisis sooner than it moves. Your proactive position on this procedure is an important.

Listed here are a couple of extra weblog posts chances are you’ll to find useful:

What Is a Hydraulic Line Blowout?

A hydraulic line blowout happens when a hose or becoming fails all of sudden and catastrophically, inflicting pressurized hydraulic fluid to spray or gush out. Not like gradual leaks that increase through the years, a blowout occurs right away, and the consequences can also be dramatic. You could see a unexpected lack of system serve as, listen a noisy pop or hiss, or witness a high-pressure move of fluid spraying from the hose.

Commonplace Reasons of Hydraulic Hose Failure

Listed here are the most typical reasons of hose failure you’ll wish to wait for:

Abrasion: Hoses that rub towards steel portions, different hoses, or the system’s body can increase vulnerable spots and sooner or later rupture. With out right kind routing and clamps, even a brand new hose can put on down temporarily.

Over the top Drive or Drive Spikes: Hydraulic programs perform beneath intense strain, and if that strain exceeds a hose’s rated capability—particularly all over startup or operation—failure is sort of inevitable.

Growing old and Dry Rot: Hoses degrade through the years. Publicity to daylight, excessive temperatures, and chemical contaminants may cause the rubber to dry out and crack, expanding the chance of a blowout.

Contamination: Grime, steel shavings, and degraded fluid within the hose can devour away at inside surfaces, weaken reinforcement layers, and reason inside blockages that result in unhealthy strain buildups.

Fallacious Set up: Hoses which are twisted, stretched, bent too tightly, or overtightened on the fittings are some distance much more likely to fail in advance. Even one thing so simple as the usage of the incorrect bend radius can compromise efficiency.

Figuring out those reasons and the way they display up within the box is essential to catching issues early—and protecting your apparatus working longer.

Caution Indicators Prior to a Blowout

Whilst a blowout would possibly appear unexpected, hydraulic hoses nearly all the time display caution indicators sooner than they fail—if you understand what to search for. Recognizing those early signs let you steer clear of a messy, unhealthy, and costly failure.

Listed here are the most typical purple flags:

Cracks, Bulges, or Worn Spots at the Hose: Visible injury is regularly the primary clue. Search for cracks within the outer layer, spaces the place the rubber is bulging, or spots the place the outer duvet has been worn away—particularly close to clamps or the place the hose rubs towards different elements.

Uncovered Twine Braid: If you’ll see the metal braid beneath the rubber, the hose is already compromised and will have to get replaced right away. Persisted use may result in a high-pressure rupture.

Leaking at Fittings or Connections: A gradual drip or oily residue close to a becoming may point out a free connection or a seal beginning to fail. Ignoring it will permit the leak to irritate or escalate right into a blowout beneath strain.

Unexpected Drops in Drive or Efficiency: In case your system begins performing slow otherwise you realize a dip in hydraulic responsiveness, it can be because of an inside hose failure or blockage. This sort of failure is tougher to peer however no much less severe.

Hissing, Whistling, or Rubbing Noises: A high-pitched sound close to a hose can point out a pinhole leak—or air being pulled into the gadget. Rubbing sounds may imply the hose is scraping towards the system body and dressed in thru.

Stiffness or Brittleness When Flexed: All over inspection, gently flex the hose. If it feels strangely stiff, brittle, and even crunchy, it’s most probably elderly previous its provider existence and at better possibility of failure.

Operators and condo technicians will have to make those inspections a regimen a part of day by day apparatus tests. Catching a $50 hose downside lately can save you a $5,000 restore the next day to come—to not point out the misplaced source of revenue whilst a system is out of provider.

Prevention Methods for Contractors and Apartment Fleets

Combating hydraulic line blowouts doesn’t require pricey equipment or complicated procedures—it simply takes consistency, a pointy eye, and the proper portions. Whether or not you’re working your individual system or managing a fleet, adopting a couple of easy behavior could make the entire distinction, supplying you with a way of safety and regulate.

1. Carry out Day-to-day Walkaround Inspections

Get started and finish on a daily basis with a snappy hose take a look at. This easy but an important step let you spot indicators of wear and tear, leaks, or rubbing sooner than they escalate right into a blowout. Pay shut consideration to spots the place hoses bend or cross thru tight areas.

2. Change Elderly Hoses—Even though They Glance Effective

Hoses degrade from the interior out. If a hose has been in provider for years or uncovered to harsh environments, it’s higher to switch it proactively than watch for it to fail.

3. Use Right kind Routing and Beef up

Fallacious routing ends up in twisting, kinking, and rubbing—all of which shorten hose existence. Use clamps, grommets, or protecting sleeves to forestall touch with sharp edges or shifting portions.

4. Make a choice the Proper Hose for the Task

Fit the hose’s specs (strain score, temperature tolerance, bend radius) to the applying. Underrated or over-flexed hoses are a lot more prone to fail.

5. Educate Operators to File Early Caution Indicators

Your group is your first defensive line. Educate operators what to wait for and inspire them to talk up when one thing turns out off.

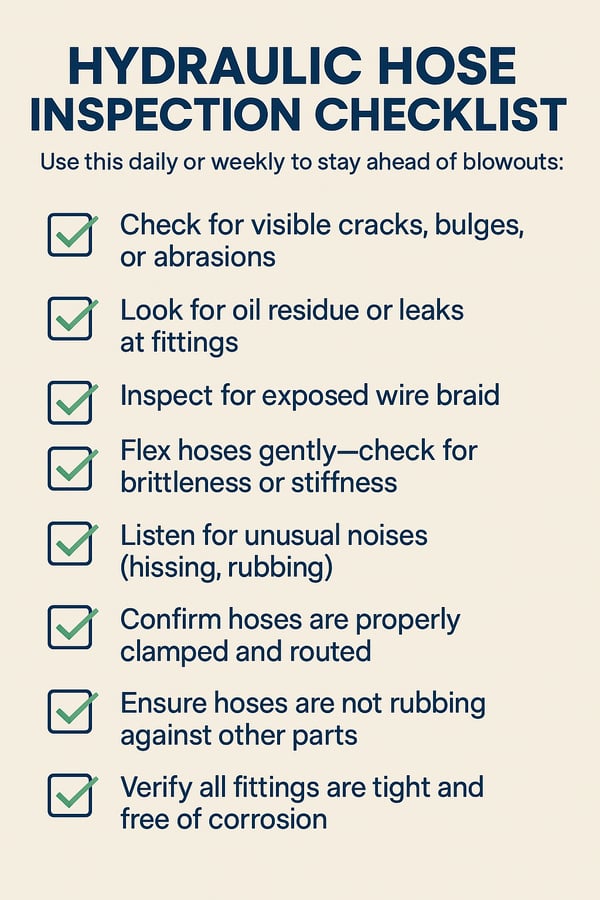

Hydraulic Hose Inspection Tick list

What to Do If a Blowout Occurs

Even with the most productive repairs practices, hydraulic hose blowouts can nonetheless happen—particularly beneath challenging stipulations. Figuring out what to do within the second can offer protection to your apparatus, your group, and your final analysis.

- Close Down the Device In an instant: Once a blowout happens, prevent running the apparatus. Proceeding to run a system with a ruptured line may cause additional injury to hydraulic elements and unfold contamination all the way through the gadget.

- Depressurize the Machine Safely: Prior to analyzing or dealing with any hydraulic traces, relieve the strain within the gadget. Pressurized fluid can nonetheless break out even after a blowout, posing a significant protection possibility.

- Comprise and Blank Up Spilled Fluid: Hydraulic fluid is hazardous to the surroundings and slippery at the jobsite. Use absorbent fabrics and apply right kind disposal procedures. Apartment companies, specifically, will have to file and blank up spills temporarily to handle compliance and popularity.

- Determine and Tag the Failed Hose: Find the purpose of failure and tag the hose for substitute. In the event you’re a part of a staff, this is helping technicians or mechanics find the issue quicker and forestalls unintentional reuse.

- Change With the Proper Hose: Keep away from the temptation to “make do” with no matter is to be had. At all times substitute the hose with one that fits the unique specifications for strain score, diameter, duration, and temperature tolerance. The usage of the incorrect hose may result in some other failure—quicker.

- Investigate cross-check Surrounding Elements: A blowout generally is a symptom of deeper problems, equivalent to a clogged filter out, over-pressurized gadget, or misrouted hose. Make an effort to check out adjoining traces, fittings, and connection issues sooner than placing the system again to paintings.

Conclusion

Hydraulic hose blowouts are greater than only a mess—they’re a pricey, unhealthy interruption that the majority operators and condo fleets can’t find the money for. Thankfully, they’re additionally one of the preventable screw ups on a system. With common inspections, right kind routing, and well timed substitute, you’ll establish and cope with issues sooner than they escalate into pricey downtime or broken apparatus.

In the event you’re able to take a proactive solution to hydraulic gadget repairs, Texas Ultimate Pressure is right here to assist. From substitute hoses and fittings to professional recommendation, we’re your spouse in protecting compact apparatus working sturdy.

Want assist discovering the proper hydraulic pumps and ultimate drives? Touch Texas Ultimate Pressure lately for speedy delivery and dependable toughen.