Mass bushes development is taking the development business via typhoon, and there are not any indicators of it slowing down. Main forecasts from Polaris Marketplace Analysis venture the worldwide CLT marketplace to triple from USD 1.1B to a few.7B via 2030. Inventions selling value relief and potency are serving to widen the mass bushes marketplace. Within the following article, it discusses a couple of examples of ways Simpson Robust-Tie helps on this effort.

The onsite installation of heavy, large-scale mass bushes parts can constitute 30%–50% of a mass bushes construction’s value. Set up delays on a mass bushes web site can disclose unprotected wooden components to water, inflicting useless remediation prices. Simpson’s mass bushes product building workforce components the overall value of possession in developing our newest mass timber merchandise, placing equivalent attention into the wishes of the engineer and the installer. This has driven our workforce to innovate and design answers that make sure dependable, rapid, environment friendly set up onweb site — all whilst making 0 compromises at the power or efficiency of the structural connection.

Not like the Eu marketplace, the place mass bushes is used considerably in house and low-rise development, right here in america and Canada we usually practice mass bushes in higher packages. Our mass bushes initiatives are typically large-scale and feature many connections. Because of this, we’ve got occupied with making the lives of the set up contractors as simple as imaginable. This is among the core riding rules for creating our new HSKP™ and SCBH™ column-to-beam connection techniques.

The HSKP heavy seated knife plate is among the maximum cutting edge mass bushes merchandise to hit the marketplace lately and is the primary high-capacity column-to-beam connector that delivers 45°-angle screw set up with out the will for angled washers or expensive customized milling of the hanger. So how did we pull this off?

Our workforce leveraged a long time of precision manufacturing to broaden a 45° stamped and entirely built-in screw guiding gadget. This innovation considerably reduces the everyday value of this connection taste, taking out 45° washers and reducing the choice of screws required — thereby dashing up the set up time for the contractor. And whilst saving 15–20 mins on a connection set up may now not appear to be a large deal, believe a standard mid– to very large venture with 1,000 or extra connections and the way a lot time all that set up may just take.

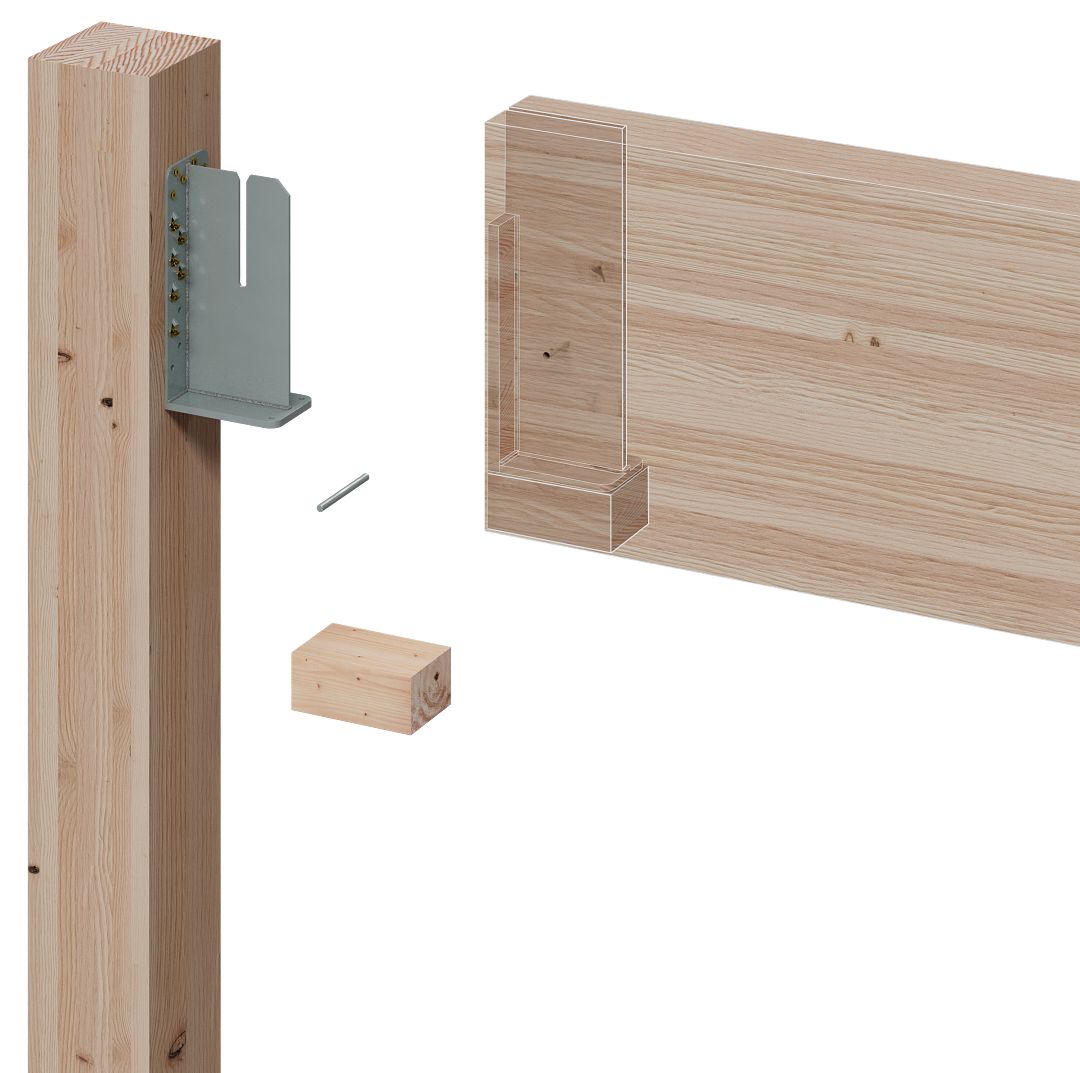

The SCBH metal hid beam hanger takes an cutting edge solution to scale back set up and customized fabrication prices via bearing in mind wood-to-wood and steel-to-wood (welded) packages whilst providing set up tolerances 3 to 5 instances more than conventional hid hanger answers. Extra forgiveness at the connector manner much less shimming and pulling of structural contributors to put in beams and columns to specification. And no more wasted time between part placements on what are usually extremely orchestrated and tightly deliberate erection schedules.

Protecting in thoughts all of the venture stakeholders, installers, engineers, and our home North American marketplace’s distinctive wishes, Simpson Robust-Tie will proceed to advertise wider adoption of mass bushes development via serving to our shoppers scale back prices and build up productiveness with good, installation-ready answers.