Your hydraulic apparatus has many alternative hydraulic connectors, and it’s just right to understand the differing types. On this Store Communicate Weblog submit, we’ll speak about hydraulic connectors (threaded, flange, and short disconnect) — together with how they paintings and the place you’re more likely to to find them.

Listed below are every other Store Communicate Weblog posts you may to find of passion:

Figuring out Hydraulic Connectors

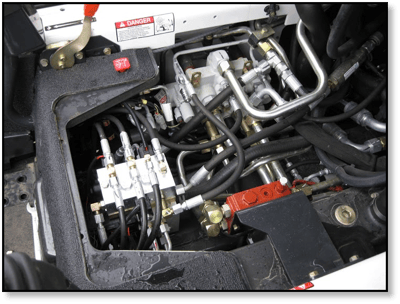

Hydraulic connectors are very important portions of the hydraulic device that energy your apparatus, permitting hydraulic fluid (generally beneath excessive stress) to transmit power and tool the place wanted, together with your ultimate pressure motors. Those connectors are designed to resist excessive stress and make sure a leak-free connection.

Figuring out the serve as and design of hydraulic connectors is very useful for correctly running hydraulic programs. Other hydraulic connectors serve particular functions and are decided on in response to the device’s necessities, so let us take a look at the more than a few varieties.

Commonplace Sorts of Hydraulic Connectors

Commonplace sorts of hydraulic connectors come with short couplings, threaded connectors, flange connectors, and push-to-connect fittings. Each and every sort has its distinctive options and packages, and they are able to be arranged into 3 elementary varieties:

- Threaded connectors

- Flange connectors

- Fast disconnect connectors

Fast couplings are in style for his or her speedy and simple connection and disconnection, whilst threaded connectors supply a safe and dependable connection. Flange connectors are repeatedly utilized in high-pressure packages, and push-to-connect fittings are handy for fast meeting.

Threaded Connectors

Nationwide Pipe Thread (NPT) connectors are a standardized form of becoming that joins pipes and fittings and may also be present in plumbing, gasoline traces, and air traces. NPT connectors’ packages come with plumbing (cold and warm water traces), gasoline traces (e.g., herbal gasoline and propane), and compressed air traces.

Those connectors have tapered threads which might be extra slender on the finish. The aim of tapered threads is to create an overly tight seal. That’s some of the issues that stands proud about NPT connectors: they succeed in a extremely dependable, sturdy seal. NPT connectors are made out of robust, corrosion-resistant metal, brass, and stainless-steel.

British Usual Pipe Becoming (BSPP), or British Usual Pipe Mechanical, are parallel thread connectors for pipes and fittings. You’ll to find them in the United Kingdom, Europe, Asia, Australia, New Zealand, and South Africa. In the USA and Canada, NPT threads are extra commonplace. They’re present in low-pressure plumbing and gasoline traces, hydraulic and pneumatic programs, gauges, and instrumentation.

Those connectors have a relentless diameter alongside their duration and will succeed in a decent seal the usage of an correctly sized o-ring or washing machine. Their threads also are made out of brass, metal, and stainless-steel just like the NPT connectors. In the end, BSPP connectors are standardized by way of ISO 228-1 and are available sizes denoted by way of “G” adopted by way of a bunch (e.g., G1/4, G1/2, G3/4).

British Usual Pipe Taper (BSPT), often referred to as Pipe Taper or Conical Thread, makes use of a tapered thread for connecting pipes and fittings and is utilized in the similar areas as BSPP connectors. Like NPT connectors, they don’t want any additional sealants in maximum packages and are made out of brass, metal, and stainless-steel. Like BSPP connectors, they’re standardized by way of ISO 7-1 and are available more than a few sizes denoted by way of “R” adopted by way of a bunch (e.g., R1/4, R1/2, R3/4). Those connectors are present in steam traces, hydraulic and pneumatic programs, and high-pressure plumbing and gasoline traces.

BSPP and BSPT threads don’t seem to be interchangeable with different thread requirements like NPT. There are going to be variations in thread attitude, diameter, and pitch — and a mismatch can result in harmful leaks.

Flange Connectors

A hydraulic flange connector is a fully very important part that you can’t do with out in hydraulic programs to glue other sections of pipe, tube, or hose. It guarantees that fluids can go via easily and with none leaks, even beneath excessive stress. In contrast to conventional connectors that use threaded or compression fittings, hydraulic flange connectors use a flange and bolts to determine an especially tight and safe connection. This design makes set up and upkeep a breeze in comparison to different connection strategies.

The flange a part of the connector usually has a chain of holes round its perimeter for bolts to go via, securing the flange to a mating piece with a identical bolt development. This creates a strong seal that may maintain the excessive pressures standard in hydraulic programs. The seal is ceaselessly bolstered by way of striking O-rings or gaskets between the flanges to make sure no leakage.

Flange connectors are most well-liked for his or her sturdiness, reliability, and skill to handle a decent seal beneath various stress and temperature prerequisites.

Blind Flanges: Those are cast discs that clean off a piping device’s finish or seal a gap. It is used for separating sections of a hydraulic device or when long term expansions are thought to be.

Captive Flanges: This sort of flange is built-in into the hose becoming for an overly safe connection in a position to dealing with excessive pressures. You’ll see those in high-vibration or high-pressure packages.

Integral Flanges: Those flanges are manufactured as a unmarried piece with the hose becoming, offering a powerful and leak-proof connection. They’re repeatedly utilized in high-pressure packages the place a competent connection is very important.

Lap joint flanges: Those flanges consist of 2 halves that clamp across the stub ends of a pipe. They’re a sensible choice for packages the place it is important to disassemble the joint continuously or when made out of a subject material this is tough to weld.

SAE Flanges (Code 61 & Code 62): Those are designed in step with the Society of Automobile Engineers (SAE) requirements. Code 61 refers to standard-pressure flanges, whilst Code 62 designates high-pressure flanges. Those are repeatedly used as a result of their dependable sealing capacity and simplicity of meeting.

Screwed flanges: Those flanges screw onto the threaded finish of the pipe and paintings neatly for low-pressure packages

Slip-on flanges: Those are slipped over the top of the pipe after which welded to the pipe wall and are a sensible choice for packages the place it’s tough to weld at once to the pipe.

Socket Weld Flanges: Those are inserted right into a recessed house of a valve, becoming, or pipe ahead of welding. You’ll see them used on smaller pipe diameters in high-pressure packages.

Break up Flanges: Those consist of 2 halves bolted across the hydraulic hose or tube. Their design makes them more uncomplicated to put in and handle in tight areas or when large-diameter tubes or hoses are concerned.

Sq. Flanges: Sq. flanges are utilized in programs requiring four-bolt flanges and requiring excessive stress.

Threaded Flanges: Those are screwed at once onto a pipe with out welding and are used when welding isn’t imaginable.

Weld neck flanges: Those flanges are welded at once to the pipe, offering a powerful and leak-proof connection., and are ceaselessly utilized in high-pressure packages.

Fast Disconnect Connectors

Fast disconnect connectors are also known as short couplings or quick-release couplings. Their activity is facilitating simple, speedy, and safe connections and disconnections of hoses and pipes with out gear or specialised apparatus. Those connectors are very important in programs requiring widespread disconnection and reconnection of parts, supporting flexibility, repairs, and the facility to modify or isolate portions of the device briefly.

There are a number of short disconnect connectors, each and every designed for particular packages and pressures:

Flat Face: Those are engineered to do away with spillage and air inclusion when connecting and disconnecting — which may also be extraordinarily vital from a hydraulic cleanliness standpoint. They are perfect for packages requiring minimum contamination, comparable to in blank environments or with delicate hydraulic circuits.

Top-Power: as their title implies, those short disconnects are used with excessive pressures They ceaselessly characteristic powerful building and locking mechanisms to make sure a safe connection beneath excessive stress.

ISO A (ISO 7241-1 Sequence A and B): Those are broadly used because of a poppet valve design that minimizes leakage all the way through disconnections and connections. They’re flexible and can be utilized in more than a few hydraulic programs. The B sequence is similar to ISO A however with a rather other profile, the ISO B connectors also are broadly used and have a poppet valve design. They’re interchangeable with different ISO B connectors and are simple to wash and will reduce fluid spillage.

Sequence B is used predominantly in North The us and the chemical trade, whilst Sequence A is basically utilized in Europe and is most well-liked international for agricultural and forestry equipment.

Push-Pull: Push-pull short disconnect connectors are for simple connection and disconnection; simply push or pull the connector halves. They’re user-friendly and ceaselessly utilized in packages requiring short and widespread adjustments.

Screw Kind: Those use a threaded connection and are identified for his or her talent to resist excessive pressures and vibrations, making them appropriate for heavy-duty packages.

Snap Kind: Those hydraulic connectors use a ball lock mechanism to glue and disconnect briefly. They’re simple to make use of and supply a safe connection, appropriate for low- to medium-pressure packages.

Wing Nut: Wing nut connectors are designed for widespread guide connection and disconnection. The wing nut lets in simple tightening and loosening while not having gear.

Elements to Believe When Opting for Hydraulic Connectors

When deciding on hydraulic connectors, you’ll want to believe compatibility, stress score, subject material, dimension, and becoming sort. Selecting the proper hydraulic connector guarantees optimum efficiency and protection. It is the most important to take a look at the particular necessities of the hydraulic device and make a choice connectors that meet the ones wishes.

Upkeep and Protection Pointers for Hydraulic Connectors

Right kind repairs of hydraulic connectors is very important to forestall leaks, contamination, and device disasters. Common inspections, cleansing, and lubrication can lend a hand lengthen connectors’ lifespan and make sure dependable efficiency. Then again, protection precautions must be adopted when operating with hydraulic connectors, comparable to dressed in suitable non-public protecting apparatus and following correct set up procedures. Coaching on hydraulic device repairs and protection is the most important for combating injuries and accidents.