Within the earlier Store Communicate Weblog submit Working out ISO 4406: The Fundamentals we went over why cleanliness codes are necessary to then you definately mentioned what the ISO 4406 digit codes constitute. This time we are taking a look at the way to use ISO 4406 to set and reach cleanliness targets to your hydraulic methods.

Blank Hydraulic Fluid and Ultimate Power Motors

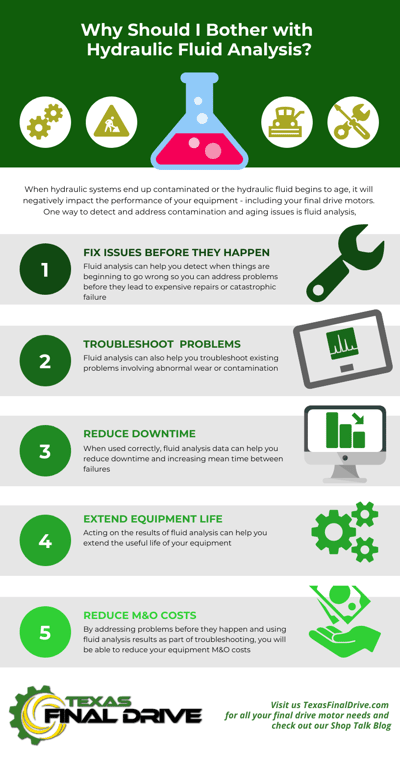

Prior to discussing ISO 4406 hydraulic cleanliness targets, let’s evaluate why that is necessary from a last force motor standpoint.

As you know, your force motor supplies the facility you wish to have to transport at the task. In case your ultimate drives have problems, it impacts your productiveness and might level to issues in other places on your hydraulic device. Particle contamination, specifically, can boost up how briskly your ultimate drives put on out, resulting in dear and even irreparable injury. And the cleaner your hydraulic fluid, the simpler your ultimate drives will carry out and the longer they’re going to closing.

Steps to Attaining ISO 4406 Cleanliness

Listed here are the stairs to pursuing cleanliness targets

- Make a choice an acceptable goal ISO code.

- Download your apparatus’s present ISO particle counts.

- Examine the place the contamination is coming from.

- Put into effect business easiest practices for cleanliness.

- Repeat 2 and four till the objective price is reached.

- Take care of fluid cleanliness.

Now let us take a look at each and every of those steps for my part.

Step #1: Make a choice an acceptable goal ISO code

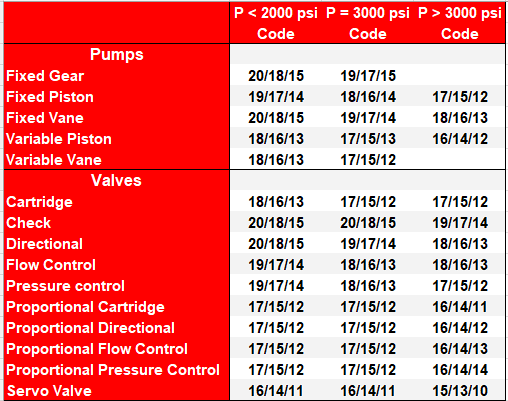

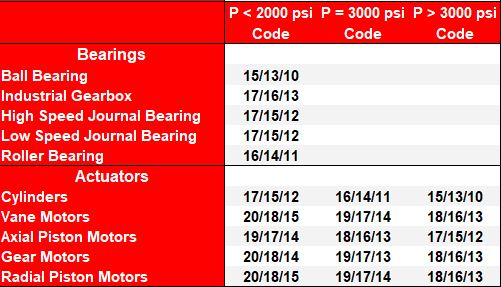

Tables 1 and a couple of supply recommended goal cleanliness for more than a few parts inside of a hydraulic device.

Desk 1. ISO 4406 Codes for Pumps and Valves

Desk 2. ISO 4406 Codes for Bearings and Actuators

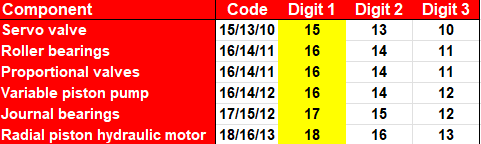

Let’s say your compact apparatus hydraulic device reduction is at 3,500 psi. It has a variable piston pump and a radial piston motor. Desk 1 suggests that you just will have to intention for 16/14/12 for the pump and 18/16/13 for the motor. Having a look at Desk 2, we all know that magazine bearings and curler bearings are used within the device. Let’s summarize what we have now to this point:

- Variable piston pump: 16/14/12

- Radial piston hydraulic motor: 18/16/13

- Curler bearing: 16/14/11

- Magazine bearings: 17/15/12

At pressures more than 3,000 psi, essentially the most delicate element can be a servo valve with a goal ISO price of 15/13/10. Proportional values will be the 2nd maximum delicate, with 16/14/XX values.

Let’s take what we all know and put it so as:

In a super global, we’d intention for essentially the most stringent code: 15/13/10 — however actual global packages require sensible answers. Aiming for that code can be price prohibitive and pointless. To succeed in that degree of cleanliness, striking a filter out upstream of crucial servo valves or different parts that require extraordinarily stringent ranges of cleanliness can be simpler. Additionally remember the fact that those are tips, no longer laborious and speedy regulations.

Having a look on the numbers, maximum parts of pastime to us have a Digit 1 of 16. That may be a excellent beginning position … and it sort of feels like 16/14/11 or 16/14/12 can be a promising goal.

Step #2: Download your apparatus’s present ISO particle counts.

To get some course on reaching your cleanliness purpose, you’ll want fluid research carried out on a pattern of your fluid. You’ll download the ones particle counts with the correct apparatus or ship hydraulic fluid samples away for analysis. When you get the research again, you’ll be able to see how smartly your present state compares on your goal. You’ll steadily have your research carried out through the apparatus producer, as is the case with corporations like Bobcat and Caterpillar.

Step #3: Examine the place the contamination is coming from.

You’ll additionally want to monitor down the in all probability assets of contamination. This newsletter from Energy and Movement is a brilliant useful resource: Working out Hydraulic Fluid Contamination. For particle contamination, right here only some of the ones soruces:

Step #4: Put into effect business easiest practices for hydraulic cleanliness.

We’ll discuss this within the subsequent weblog submit on this sequence. Within the interim, take a look at our weblog submit on Combating Hydraulic Contamination Problems.

Step #5: Repeat 2 and four till the objective price is reached.

Attaining the extent of cleanliness you intention for received’t occur right away, and there can be some trial and mistake till you find what’s sensible for you and the way to succeed in it.

Step #6: Take care of fluid cleanliness.

Keeping up fluid cleanliness is very important to combating contamination-related problems. Listed here are some methods that may be hired to succeed in and care for the fluid cleanliness ranges you wish to have:

- Common fluid filtration: Make use of filtration methods to take away contaminants from the fluid right through operation.

- Right kind fluid garage and dealing with: Use blank bins and kit for fluid garage and switch to attenuate contamination.

- Rigorous repairs practices: Put into effect strict repairs procedures to forestall leaks and ingress of contaminants right through provider actions.

Conclusion

At Texas Ultimate Power, we wish your apparatus to run easily and hydraulic contamination is among the main stumbling blocks to that. Contamination, if unnoticed, can break your ultimate force. Surroundings cleanliness objectives is a good way to give protection to your whole hydraulic device and prolong the lifetime of your apparatus and parts. It will possibly additionally save you expensive downtime and stay the efficiency of your device as a complete at optimal ranges.