Your compact apparatus and ultimate drives rely at the clean drift of hydraulic fluid to transmit energy and regulate movement. On the other hand, the presence of contaminants within the hydraulic fluid can adversely have an effect on no longer simply device efficiency however its longevity as neatly. And that’s the place ISO 4406 comes into play.

On this Store Communicate Weblog submit, you’ll be told why cleanliness codes must be necessary to you, adopted by way of what the ISO 4406 digit codes constitute.

Listed below are a couple of different Store Communicate Weblog posts you may to find useful …

What’s ISO 4406?

ISO 4406 is a world usual established by way of the Global Group for Standardization (ISO). It defines a code for classifying the extent of contamination in hydraulic fluids. This code supplies a standardized way for measuring and expressing the quantity and measurement of debris found in hydraulic fluid. In the event you’re desirous about its contents, right here’s a hyperlink to an older model: ISO-4406-1999.

Particle Contamination in Hydraulic Fluids

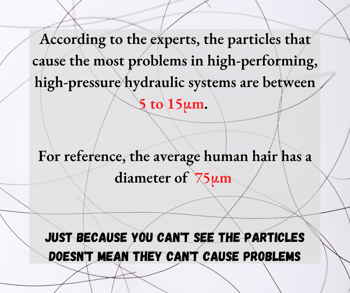

Particle contamination refers to forged debris or different impurities within the fluid. Greater debris may cause put on and harm to hydraulic parts, decreasing potency, expanding noise, and eventual failure. Smaller debris, whilst much less prone to purpose instant harm, nonetheless give a contribution to sped up put on and decreased device lifespan — they steadily can’t be observed by way of the bare eye.

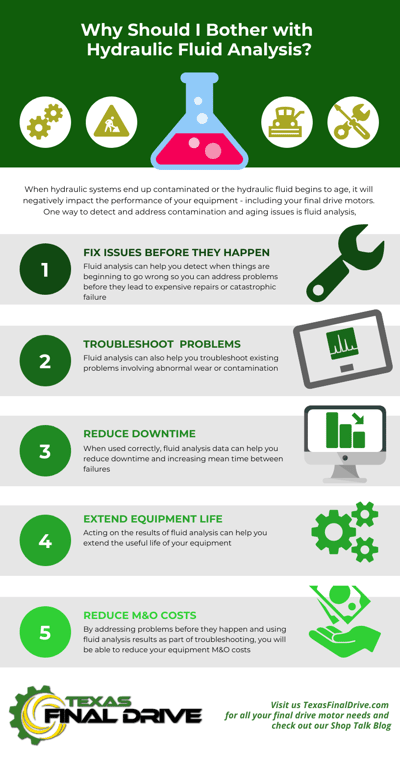

The cleanliness of your hydraulic fluid will also be assessed thru fluid research, which incorporates a particle rely that tells you concerning the measurement and collection of debris the use of the ISO 4406 code. That very same code too can function a goal when bettering and keeping up the cleanliness of your hydraulic fluid.

Why ISO 4406 Cleanliness Codes Are Vital to You

The ISO 4406 cleanliness code supplies precious details about the contamination stage of your hydraulic fluid. This is helping you lengthen the helpful lifetime of your device and the parts inside of (like your ultimate force motor and pumps) whilst serving to you optimize apparatus efficiency.

For instance, ISO 4406 cleanliness codes let you assess the suitability of hydraulic fluid for particular programs. Other hydraulic techniques have various cleanliness necessities, and trendy machines are extra vulnerable to harm from particle contamination.

Fluid research and the codes additionally let you track fluid cleanliness over the years to trace adjustments in contamination ranges. Gazing the adjustments in contamination ranges lets you deal with problems prior to they grow to be catastrophic for your device and your ultimate force motors.

Cleanliness considerably affects the helpful existence and productiveness of your apparatus. As a result of this, it may be really useful to determine and handle fluid cleanliness objectives in response to apparatus specs and working stipulations. The ISO 4406 cleanliness codes are a useful gizmo in carrying out this.

Fundamentals of the ISO 4406 Codes

Now let’s check out the fundamentals …

ISO Digits

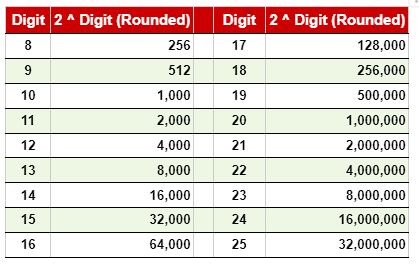

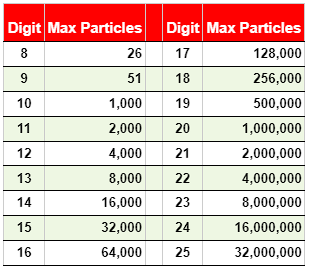

The particle rely associated with an ISO digit is represented when it comes to the issue 2 and, when divided by way of 100, represents the most collection of debris present in 1 ml of hydraulic fluid. I do know that sounds slightly complicated, so right here’s a very good desk to lend a hand us perceive this:

Desk 1. ISO Digits and Components of two

So 15 is roughly 2^15, which supplies us 32,000 when rounded. 21 offers 2,000,000 when rounded. However that also isn’t what the digit represents. We need to do some bit extra math.

To get the true particle rely related to a digit, we wish to divide the quantity by way of 100. So right here’s the utmost particle counts associated with the digits:

Desk 2. Most Selection of Debris Related to ISO Digits

In case your oil research comes again with 9 for debris with a most measurement of four microns, then you possibly can glance up 9. 9 corresponds to 512. To get the true particle rely, you possibly can divide 512 by way of 100 to get 5.12, roughly equivalent to five debris. Which means that your hydraulic fluid has not more than 5 debris with a measurement of 14 microns.

3 Digit Iso Code

3 digits constitute an entire particle rely.

- The primary digit corresponds to most debris better than 4 microns.

- The second one digit corresponds to final debris better than 6 microns.

- The 3rd digit corresponds to the utmost collection of debris better than 14 microns.

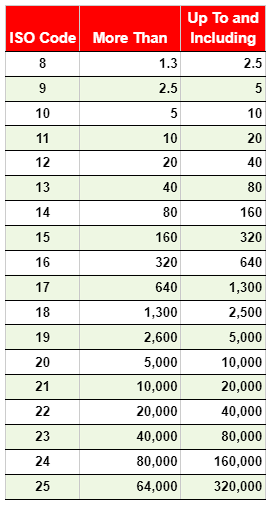

Right here’s a desk that will help you know how this works.

Desk 3. ISO Code and Related ppm (portions according to million)

Believe this code 16/14/11, in most cases known as a just right ISO worth for contemporary hydraulic fluid. Regarding our desk, we see that …

- There are as much as 640 debris in 1 ml of fluid which can be 4 microns or much less

- There are as much as 160 debris in 1 ml of fluid which can be 6 microns or much less

- There are as much as 20 debris in 1 ml of fluid which can be 14 microns or much less

Conclusion

ISO 4406 performs a a very powerful function in keeping up the cleanliness and integrity of hydraulic fluids, making sure optimum efficiency and longevity of hydraulic techniques. Through figuring out the ISO cleanliness code and enforcing efficient fluid contamination regulate measures, apparatus operators can safeguard their hydraulic techniques in opposition to expensive downtime and untimely failure.