With all of our communicate of ways spectacular radial piston motors are when used to energy skid steer brush cutter attachments, we concept we must solution your subsequent query… How do radial piston motors paintings?

Key Take Aways

- A radial piston motor has pistons organized in a celebrity formation across the output shaft.

- At the finish of each and every piston is a curler that permits the piston to trip round an eccentric cam ring.

- Hydraulic power pushes the piston towards the eccentric cam ring, the lobes within the cam ring push the piston again, inflicting rotation power to happen.

What’s a Radial Piston Motor?

As an advent, radial piston motors is one of those hydraulic motor this is repeatedly used to energy equipment akin to forklifts, skid steers and excavators. It’s regularly used as a “direct pressure” motor, no longer wanting aid gears, and can also be bolted immediately to trip parts.

The truth that it’s utilized in prerequisites that require top energy isn’t a accident. By means of design, radial piston motors provide top torque, low velocity, clean serve as and feature an extended provider existence than different commonplace hydraulic motors when used and maintained correctly.

How Does a Radial Piston Motor Paintings?

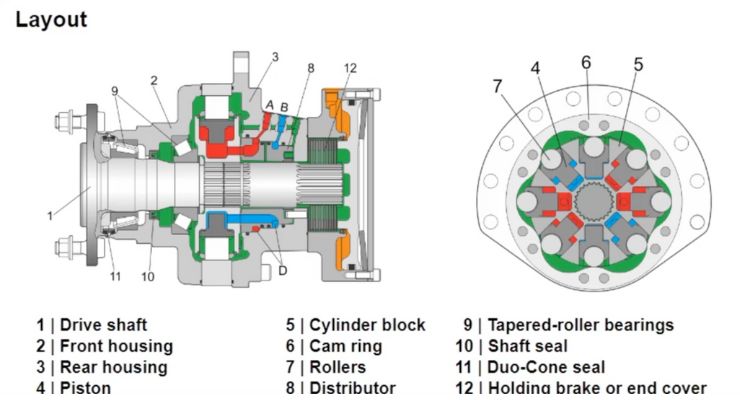

There are two primary parts that wish to be understood when discussing how a radial piston motor works. One is the the eccentric cam ring, and the opposite is the pistons themselves.

Eccentric Cam Ring

An eccentric cam ring is a hoop this is mounted internally across the inside the motors housing which the pistons push towards with a purpose to provide torque and rotation to the output shaft.

The trick to the radial piston motor operating is the truth that the cam ring is “eccentric”. Which means that as an alternative of the hoop having a uniform form, it has lobes and valleys constructed into it. That is crucial attention as we will be able to speak about later.

Radial Pistons

Because the title implies, a radial piston motor has pistons organized in a “ray” across the output shaft. You’ll be able to additionally bring to mind those pistons as being organized in a celebrity formation, with one finish hooked up to the output shaft, and the opposite lead to touch with the eccentric cam ring.

At the finish of the piston is a “curler” which permits the piston to trip alongside the cam ring, which as you’ll be able to see, is essential to the radial piston motors operation.

How Do They Paintings In combination?

Pressurized hydraulic oil is shipped out of your skid steer on your brush cutters radial piston motor. The oil is used to pressurize the pistons as they’re travelling down the cam ring lobes. The piston, with it is curler pushing towards the cam lobe is what creates the rotational power.

Because the piston reaches the ground of the valley within the cam ring, it’s going to not be receiving pressurized oil. Because the piston is driven again up the following cam lobe it’s going to go back the oil inside of its cylinder to the go back line.

As soon as the piston is on its approach backpedal the following cam lobe, it’s going to as soon as once more be receiving pressurized oil and pushing towards the cam ring so as to add extra rotational power. In spite of everything, each time a piston is rolling down a cam lobe, it’s pressurizing and offering rotational torque.

Just like different varieties of piston engines, a radial piston motor can have greater than piston making use of energy at a time. This guarantees that steady energy is carried out thru out all the rotation of the pressure shaft.

Test Out This Video Underneath From The “Rotary Energy” Youtube Channel For A Video Of This In Motion.

Different Brush Cutter Motor Parts

Your brush cutters radial piston motor will probably be accompanied with a distributor and manifold block that regulates and controls the power of the hydraulic fluid coming into and exiting the hydraulic motor.

Brush cutters with radial piston motors will regularly require a case drain line. This relieves extra hydraulic power from the motor and is vitally vital.

In case your skid steer brush cutters motor calls for a case drain line, even the usage of the comb cutter momentarily with out the case drain will undoubtedly injury the motor and void your guaranty. Test with the producers suggestions.

As with all hydraulic motor, there will probably be a number of bearing assemblies to permit shifting portions to rotate freely. Seals on each ends of the motor are used to stay lubrication within the motor and mud and dust out.

Radial Piston Brush Cutter Motors – Different Concerns

It is extremely vital to stay the hydraulic fluid blank when the usage of any radial piston motor. Pistons within the motor are manufactured to tight tolerances, and any quantity of grime or particles will briefly contain the motor.

Brush cutters particularly have a tendency to throw mud grime and particles each which approach. A easiest practise is to make sure that that the hydraulic couplers are completely blank prior to connecting or disconnecting them on your skid steer.

Commonplace Radial Piston Motor Specs

-

Radial piston motors are repeatedly in-built 150cc to 3000cc displacements, on the other hand, when utilized in skid steer brush cutter programs, 150cc to 250cc is commonplace.

-

Radial Piston Motors are most often designed with a most 100 to 900 revolutions according to minute. When used with a skid steer brush cutter, the RPM will probably be at the decrease finish of this vary.

Conclusion

Radial piston motors are the easiest method to energy your skid steer brush cutter. With its easy direct pressure, low velocity, top torque features, it’s an evident selection for Serious Accountability Brush Cutters.

If you wish to speak about additional on how those motors paintings, or every other skid steer hydraulic motor, be at liberty to succeed in out to the creator immediately the usage of the hyperlinks supplied.