A slab-on-ground construction calls for a correctly ready floor sub-base. A solid and durable floor base reinforce is important to stay the concrete slab degree and haul for an extended length with out agreement. Here’s a fast information on pouring a concrete slab at the floor.

|

| Symbol Credit: https://www.freyssinet.com.au/ |

1. Decide the Intensity of the Slab

Decide the intensity of the slab required and make a decision whether or not the slab is to be laid in line or above floor degree. Test the drainage route and web site laws to arrange the web site with none water flooding problems because of wrong sloping.

2. Get started Excavating the Slab Intensity

Get ready the site of the bottom, within the measurement of the slab (duration and breadth). If you want the slab in-line with the bottom, dig the slab house to the desired intensity of the slab. Skilled experience right here mean you can plan correctly for digging. Dig uniformly that the ground house is equal to the highest house of the slab pit. Use grime or soil to fill any divots or holes provide.

3. Hose down the Earth and Compact the Subgrade

Hose down the soil via spraying it with water in order that it holds in combination. Do it in periods in order that as a substitute of turning into a pool, the unfastened earth holds in combination. Tamp it, compact it, and degree the subgrade floor, till your footprints on it are nearly invisible.

4. Lay the Base

The most productive base for a concrete slab is a mixture of coarse and advantageous mixture to shape a compactable base that forestalls agreement and promotes drainage.

5. Compact the Base

Use a hand or mechanical tamper to compact the gravel base. In most cases, the bottom layer is positioned in layers of two inches (no more than that) and compacted, following the layer. The thickness of the bottom layer for a concrete slab can vary between 4 to six inches. A base of 6 inches is used for concrete driveways subjected to heavy-duty a lot. Above the bottom, vapor limitations or a damp-proofing layer is supplied according to the requirement of the web site. It relies on how prime is the water-table degree of the web site.

|

| Concrete Slab at the Flooring With Vapor Barrier © 6DProjects |

6. Get ready the Formwork for Concrete Slab

The formwork is ready according to the measurement of the slab. Picket, foam forums, and so forth can be utilized for formwork. Position stakes in periods and safe them to supply additional reinforcement for the formwork.

|

| Stakes Beef up for Formwork |

Follow free up agent throughout the formwork for simple elimination from the concrete slab. Silicone rubber or cooking oil can be utilized for this function.

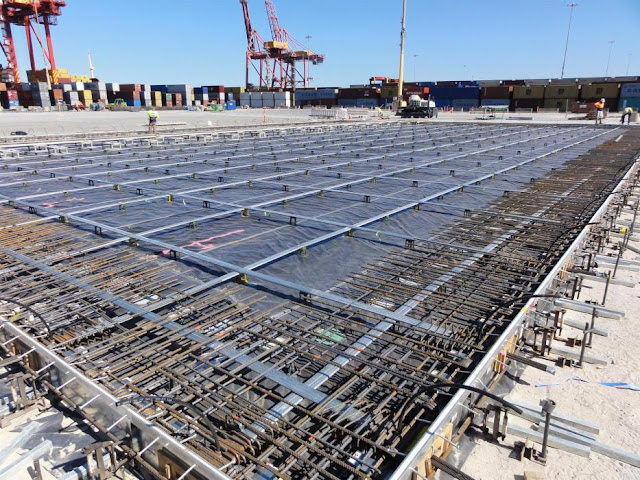

7. Position Reinforcement on Formwork

Reinforcement bars aren’t important for concrete slabs with thicknesses lower than 4 inches. The desired rebars are positioned in grids. Carry in combination the rebars the use of rebar ties. Chairs can be utilized to stay the rebars above the peak of the bottom.

As in line with ACI 318-2019, 20.5.1.3 Specified Concrete Quilt Necessities, a canopy of three inches must be supplied for concrete slabs immediately involved with the bottom, by way of quilt blocks. For slabs of small thicknesses, cord mesh will also be positioned as reinforcement as a substitute of metal reinforcement bars.

8. Pour Recent Concrete on Formwork

The concrete of required energy and houses is poured both via able combine concrete supply or as a DIY mission. However with the rise within the house and intensity of the slab, it is strongly recommended to enlist skilled lend a hand. The concrete slab is compacted, leveled, and completed. The slab is left for curing to achieve energy and to be used.

American Concrete Institute (ACI) Committee recommends a minimal curing length akin to concrete achieving 70 p.c of the required compressive energy. The continuously specified seven-day curing frequently corresponds to roughly 70 p.c of the required compressive strengths. It’s excellent to supply a 28 days curing length for concrete slabs with massive thicknesses and for primary energy achieve.

What’s the Price of a Concrete Slab?

The price of developing a concrete slab depends at the house of the slab, the thickness of the slab, the level of floor preparation, the kind of concrete used, the price of reinforcement, and hard work prices.

As a coarse estimate, the price of a regular 4-inch-thick concrete slab for a standard residential driveway or patio can vary from $4 to $8 in line with sq. foot. For a harder and ornamental end, a stamped or stained concrete slab would possibly price any place from $8 to $18 in line with sq. foot.